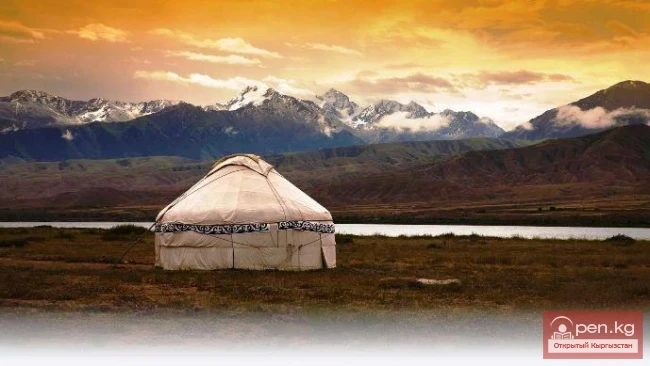

Portable Dwelling of the Kyrgyz

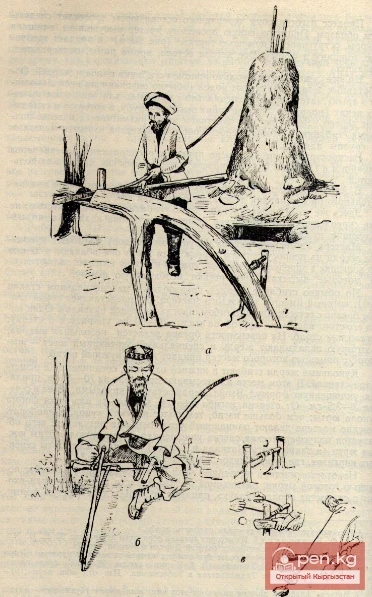

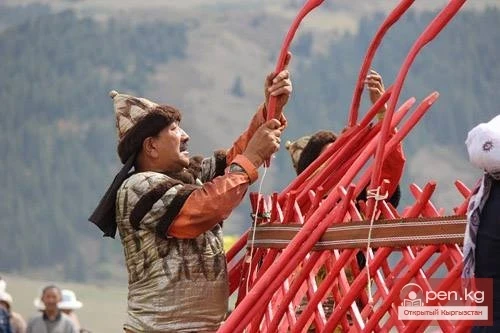

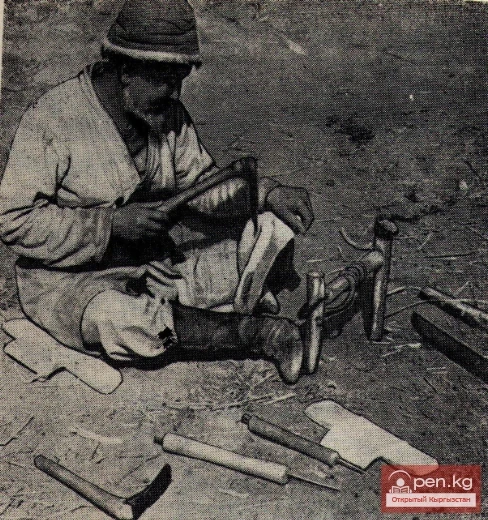

Kyrgyz wood craftsmen (zhygach usta) have mastered the production of the wooden frame of the yurt over time. The oldest among them learned this craft from their fathers and grandfathers and still cherish everything passed down to them through tradition. Usually, craftsmen made the frame of the yurt upon order, but it was also common to produce it in advance, without an order. In some cases, such work was done collaboratively by brothers living in different families. For instance, in the village of Orto-Machit in the Nookat district, the master Maatnazar had six sons. All of them inherited their father's craftsmanship and cooperated with each other to produce the frames of yurts. Recently, as the craftsmen say, they received payment in cash for their work, rather than in kind, as was customary before. One of the brothers, Amat, shared how efficiently they worked together and how they saved time by collaborating. While one craftsman could make the frame of a yurt in 20-25 days, the brothers completed it in 5-6 days.

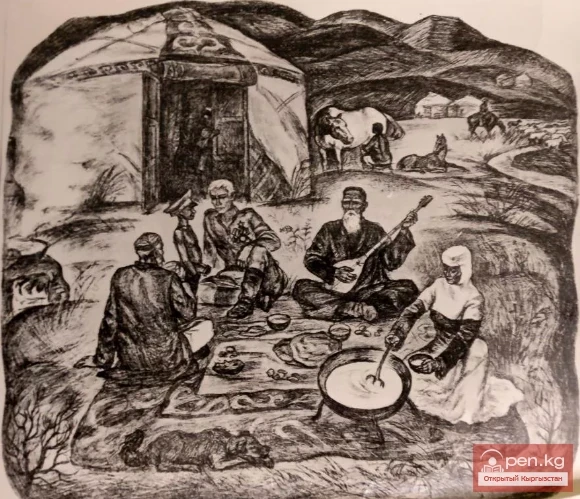

The Kyrgyz-made yurt was widely popular. It was purchased not only by Kyrgyz (including Kyrgyz from all tribal groups and Pamir Kyrgyz), but also by Uzbeks, Turks, and Tajiks.

In the south, the yurt is commonly referred to as kara uy, but more often as kyrgyz uy. The usual name in the north, boz uy, is rarely used.

The term "kyrgyz uy" is widespread throughout the Fergana foothills, including the northern part of the Osh region. This name likely reflects the distinctive features of the Kyrgyz yurt and was given by the peoples who acquired yurts from the Kyrgyz.

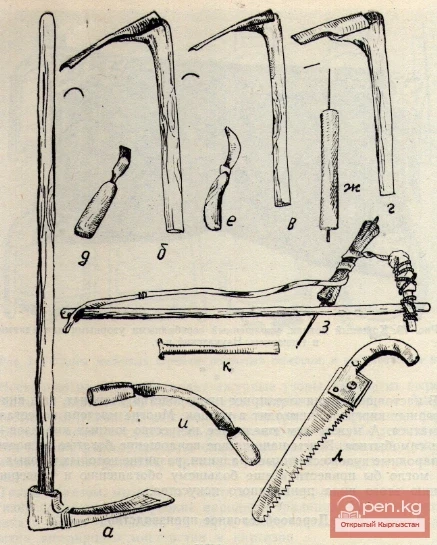

The work of making the wooden frame of the yurt is seasonal. It is usually done in the summer, outdoors. The primary material used is willow ("tal"). The Kyrgyz have always carefully cultivated these trees.

The craftsmen distinguish the following types: yellow (sary), white (ak), black (kara), and blue (kök).

They consider sary tal to be the best in terms of strength and durability. The other types, according to the craftsmen, are more prone to rapid decay. Craftsmen prefer willow over birch ("kaiyts"), as products made from the latter can change shape under moisture. Birch is only used for one architectural detail—the hoop (tunduk).

Harvesting wood takes a lot of time. A craftsman sometimes spends five to six days preparing it for the frame, selecting wood of a specific length and thickness according to the parts of the yurt being made.

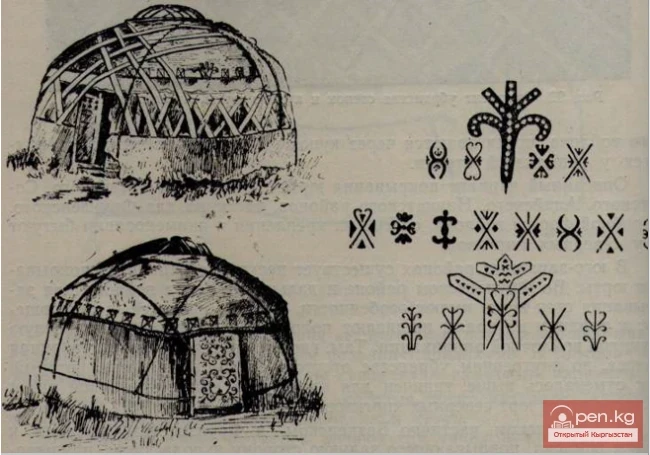

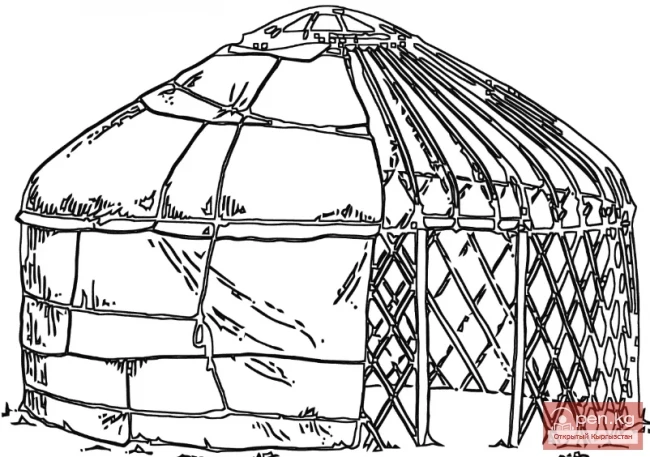

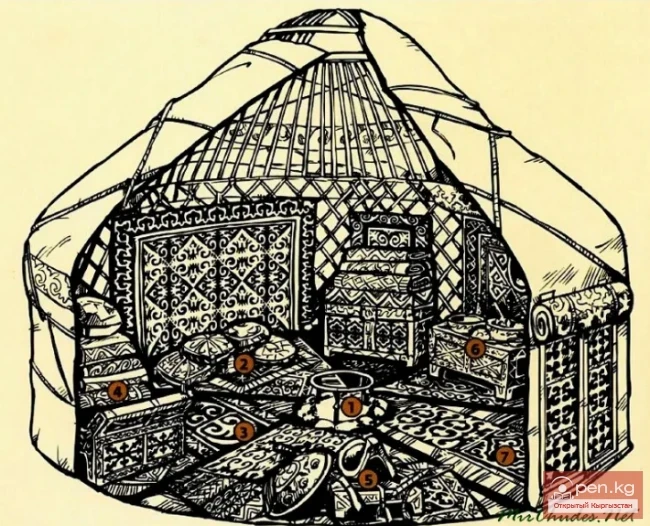

The frame of the Kyrgyz yurt consists of lattice sliding walls (kerege), made up of individual links (kanat), dome poles (uuk), the hoop ("tunduk), door frame (bosogo), and door (kaalga, eshik, ergichek, ergilchek).

The size of the yurt can vary. It is usually determined by the number of links. The smallest consists of four links, while a large one has eight to twelve. A yurt with six links is considered average. In this case, its diameter is approximately five meters, and its height is about three meters.

When making a yurt, the craftsmen carefully calculate the proportions of all its parts. They know, for example, how many dome poles are needed for a certain number of links and what their lengths should be. The height of the lattice walls, the dimensions of the hoop, and the number of openings in it for the dome poles are also taken into account. Thus, making the frame of the yurt requires special skills. Experienced craftsmen are well-known, especially since they usually produce not only the frame of the yurt but also various household items.

Dwellings of the Kyrgyz