Industry in Kyrgyzstan

The leading sector of the national economy of the Kyrgyz SSR became industry. It accounts for more than half of the gross product, includes over 130 industries producing about 4,000 types of products. Today, it produces in half a day as much industrial output as was produced in the entire year of 1924.

The volume of industrial production in the republic increased more than 700 times over the 60 years of the existence of the USSR.

In terms of the level of development of machine engineering, Kyrgyzstan ranks second in Central Asia after the Uzbek SSR, and in the production of such products as trucks, pumps, automatic lines for electric lamp factories; gas stoves, food boilers, etc. — it ranks first.

The machine engineering sector of the republic produces more than 200 types of products. Among the branches of machine engineering, the electrical engineering industry, instrument engineering, automobile manufacturing, and electronics are developing at the highest rates.

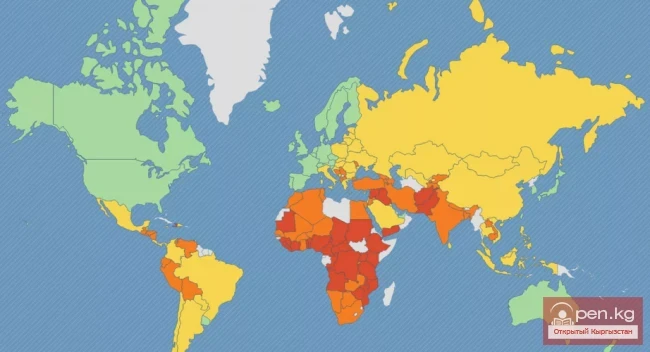

In 1959, the republic exported industrial products to only 9 countries, whereas now various electrical and physical instruments, agricultural machines, metal-cutting machines, electric motors, and many other products are supplied to 19 countries in Europe, 18 countries in Asia, and 16 countries in Africa and Latin America.

The working class of Kyrgyzstan grew at an extremely high rate, increasing by more than 320 times by 1982 compared to 1913.

In terms of coal reserves, Kyrgyzstan ranks first in the Central Asian economic region. Of the total reserves of 2.2 billion tons, more than 240 million tons are suitable for open-pit mining.

During the years of Soviet power, coal extraction increased 25 times and continues to grow. Currently, the republic accounts for more than 40% of the coal mined in all of Central Asia.

The rivers of Kyrgyzstan, flowing down from great heights along mountain slopes, not only bring life-giving moisture to fields and gardens but also immense energy. Their potential energy resources are estimated at 142 billion kWh per year. On the Naryn River and its tributaries alone, more than 16 hydroelectric power stations can be built.

Naryn is the river of friendship. Representatives of more than 40 nationalities constructed the Toktogul energy-irrigation hydrocomplex. The capacity of the Toktogul Hydroelectric Power Station is 1,200,000 kW, and the Kurpsai station is 800,000 kW.

The commissioning of the Kurpsai Hydroelectric Power Station took an extremely compressed time — just one five-year plan. Such speeds had never been seen in domestic hydroenergy construction before.

The history of the Kyzyl-Kiya coal deposit is interesting. The Kyzyl-Kiya deposit was long known to the local population: Kyrgyz shepherds extracted "burning stone" from the outcrops of layers washed by mountain streams and used it as fuel.

In 1898, district engineer Mikhailov, with the help of local shepherds, conducted the first geological surveys in the Ishma-Bulak area (now Kyzyl-Kiya) and made a claim in favor of the state.

This year is considered the official year of the discovery of the Kyzyl-Kiya deposit. The discovery of the deposits was reported by the newspaper "Turkestani Vedomosti," and immediately mining industrialists flocked to the area.

From 1901, systematic exploitation of the Kyzyl-Kiya coal mines began by private entrepreneurs. Various capitalist "partnerships" emerged one after another, but after a brief period of artisanal predatory coal extraction, the owners resold the mines. There was no talk of mechanization, electrification, or safety measures at that time. Before the revolution, 50% of Kyrgyzstan's coal was extracted here.

"Ashir, Mustafa, and three other miners worked in one face. Two drilled, three transported coal. When they encountered a soft layer, the young and strong miners extracted so much coal that their comrades could not keep up with transporting it.

Breathing heavily, they filled the carts, and the transporters took them to small trolleys. The trolleys traveled further along wooden rails covered with iron. A horse, urged on by a driver, slowly trudged along the long haul to the mine shaft, stumbling and sliding in the mud. A sooty carbide lamp hanging on the side of one of the trolleys dimly illuminated this sad procession. From sunrise to sunset, people and horses, blinded by eternal darkness, worked deep underground," — describes the work of miners in the Sulyukta mines by Kyrgyz writer Satkyn Sasykbaev in his novel "Light Underground."

During the years of Soviet power, Kyzyl-Kiya transformed into a major center of the mining industry. New mines were opened, and old ones were reconstructed. Here, for the first time in Central Asia (in 1938), underground electric locomotives and continuous miners appeared. Today, Kyzyl-Kiya remains the main supplier of brown coal in the republic.

Modern technological development allows the use of antimony in more than 200 alloys, which are used in the production of various industrial goods: battery plates, acid equipment, shells for telegraph, telephone, and electrical cables. We find it in wheel bearings for automotive and railway transport, household utensils, decorative items, semiconductors, matches, textile and rubber products, medicine, and spacecraft.

Without any exaggeration, antimony can be called a universal metal, unique in its properties.

The non-ferrous metallurgy of the republic is represented by the production of antimony, mercury, and the extraction of polymetallic ores, which actually began in the 1930s. Before the revolution, only 440 tons of non-ferrous metals were produced.

Southern Kyrgyzstan occupies a leading position in the country in antimony production. The first Soviet metallic antimony obtained at the Kadamjai Antimony Plant in 1936 was recognized as a world standard of quality at the World Exhibition in Brussels in 1958.

One of the representatives of the renowned team at the Kadamjai Antimony Plant named after M. V. Frunze is metallurgist, antimony smelter, and brigade leader Zulpuqar Mamatov. For his labor achievements, the Motherland awarded him the Orders of the "Badge of Honor," the October Revolution, and the gold medal of the USSR VDNH. He was awarded the State Prize of the Kyrgyz SSR in the field of production.

Outstanding geologists of our country, such as A. E. Fersman, A. V. Nalivkin, D. I. Shcherbakov, and others, made a significant contribution to the scientific and geological study and the creation of the antimony-mercury and polymetallic industry in the Osh region.

In 1983, there were 1,418 mechanized production lines, more than 771 automatic lines, and 767 automated and mechanized workshops and sections operating in the industry of Kyrgyzstan.

During the X five-year plan, about 100 new models of machines, equipment, devices, and instruments were created, and the production of more than 1,000 new types of industrial products was mastered, including electronic computing machines, numerically controlled machines, and others.

Many industrial enterprises in Kyrgyzstan use equipment manufactured in the GDR (Kyrgyz Woolen and Cloth, Printing Combines, "Kirgizmebel" Association), Czechoslovakia (Kant Cement and Asbestos Plant), Poland (Kainidin, Aksu Sugar Plants), and other fraternal countries.

The balers from the M. V. Frunze Agricultural Machinery Plant are sent to more than 650 addresses in our country and abroad.

The Order of the Red Banner of Labor plant of agricultural machinery named after M. V. Frunze receives 1,788 parts and materials from 195 cities of ten union republics for the production of balers.

Products from the Frunze Heavy Electromechanical Plant go to 750 addresses. The plant meets the needs of the national economy of our country and several foreign states for large electric machines — induction voltage regulators, phase regulators, electric motors.

One of the highly mechanized enterprises is the Mailisay Electric Lamp Plant. Here, more than 30 automatic lines and 30 units of automatic and semi-automatic equipment operate. Annually, the enterprise produces 335 million electric lamps of various purposes, has established the production of bulbs for food thermoses, crystal diffusers for lamps, and many other products. 20 types of electric lamps have been awarded the state Quality Mark.

The Frunze Drill Plant named after the 60th Anniversary of the USSR is considered the pioneer of the tool industry in Central Asia. Established in 1970, it is part of the All-Union Production Association "Soyuzinstrument," providing drills of various diameters and high strength to enterprises in Central Asia, sending its products to many cities of the USSR, CMEA countries, as well as to capitalist states, including Italy, France, and Canada.

Meet: FERZ — Frunze Experimental Repair Plant of the Order of the Red Banner of Labor — the pioneer of the metalworking industry. It was founded in 1926 by Czechoslovak internationalist proletarians who responded to the call of the Soviet government to help the young socialist state in creating factories in the underdeveloped regions of the country.

Today, several dynasties of the founders of "Intergelpo" — Czechoslovak proletarian workers — still work at the plant. One of them is headed by Yuri Tomashevich Glozl, a milling machine operator and holder of the "Badge of Honor" order.

The plant was one of the first in the republic to be awarded the title of "Enterprise of High Production Culture," and it has been awarded first-degree diplomas from VDNH and the Kyrgyz SSR.

During the years of the X five-year plan, the enterprise saved 750 tons of rolled black metals and saved 8 million kWh of electricity.

Every fourth worker employed in the industry of the republic works in machine engineering and metalworking enterprises. One of them is Pyotr Sanochkin, a leading lathe operator at the Frunze Experimental Electrovacuum Machine Engineering Plant, a man of inquisitive mind who approaches his work creatively.

At the All-Union competition in Moscow, he was awarded a special prize from the Central Committee of the Komsomol for excellent quality of work; he is a prizewinner of the All-Union competition for the precision of execution and the best young lathe operator in Frunze.

The volume of light industry production in the republic increased by almost 27 times by 1980 compared to 1940, and food production increased by 9 times.

PMP — "Progressive Thought — to Production" — is the name of the system of workers' participation in production management, introduced at the Frunze Instrument Engineering Plant named after the 50th Anniversary of the Kyrgyz SSR. The active participation of workers in production management allowed for a 3.5-fold increase in the economic efficiency of implementing various proposals over 5 years, more than 1.8 times increase in labor productivity, 1.5 times increase in capital productivity, and nearly tripling the level of mechanization and automation, achieving growth in production volume while simultaneously increasing the share of products marked with the Quality Mark by almost 4.5 times.

Labor initiatives have been widely implemented in the republic's enterprises: Muscovites — "Five-Year Plan for Quality — Workers' Guarantee,"

Rostovites — "Work Without Laggers," "We Will Build Ahead of Schedule — We Will Master Ahead of Schedule," Leningraders — "From the High Quality of Each Worker — to the High Efficiency of the Collective's Labor," Uralites — "Five-Year Brigade Task — with a Smaller Team," Zaporozhye residents — "Manual Labor — on the Shoulders of Machines," Kemerovo and Chelyabinsk residents — for the conservation of fuel and energy resources and metals, brigade methods of labor organization at the Volga Automobile and Kaluga Turbine Plants, cooperation of adjacent workers based on the principle of "worker relay," and others.

For many years, the Frunze factory named after the 50th Anniversary of the USSR has been competing with the Leningrad cotton-spinning factory "Vereteno," the Osh and Margilan silk factories, the Mailisay and Armenian electric lamp plants, etc.

In 1941, a knitwear factory named after A. I. Mikoyan was evacuated from Kharkov to Frunze, which had 70 workers and employees, 83 units of knitting and dyeing equipment, and 50 sewing machines. In the first year of the war, the factory produced 72,000 items: underwear, undershirts, and other products for the army.

Later, based on this factory, the Frunze Production Knitwear Association named after the 60th Anniversary of the USSR grew — now one of the largest in the light industry system of the Kyrgyz SSR. Annually, about 30 types of various products come off its assembly lines. More than 3,000 tons of textile raw materials are used in production (pure wool yarn, half-wool, paper, artificial and synthetic threads). The number of workers increased from 70 in 1941 to 4,500 by 1985. The association supplies its products to the RSFSR, Uzbekistan, Tajikistan, and Turkmenistan.

Children's and youth coats, raincoats, artificial fur coats, fur jackets for boys... Clothing with the brand of the Frunze Sewing Factory "40 Years of October" has gained recognition among buyers not only in our republic but also beyond its borders. The range of outerwear produced at the factory includes more than 40 items and is updated by more than half each year.

The collective of one of the oldest enterprises — the Frunze Cotton Spinning Factory named after the 50th Anniversary of the USSR — is known for its glorious labor achievements. The leading worker S. Kulmatova initiated the initiative "Two Five-Year Plans — for One." She successfully fulfilled her commitment and was awarded the title of Hero of Socialist Labor.

Silk produced at the Osh Silk Combine named after the VLKSM is in demand in all corners of our country. The raw material for it is the cocoons of mulberry silkworms, coming from all regions of the republic, and artificial fibers sent from several cities in Eastern Siberia and the European part of the USSR.

The combine produces fabrics of 15 varieties, and three types of products have been awarded the state Quality Mark.

Young men and women of Kyrgyzstan, with their inherent enthusiasm and romantic impulse, work in factories and plants, in fields and farms, in scientific laboratories, acquiring knowledge in educational institutions to become qualified workers. In various sectors of the national economy of Kyrgyzstan, in 1983, there were 4,704 youth Komsomol teams, comprising more than 52,000 young men and women.

On May 2, 1927, the first woolen factory named after K. Gotwald was launched in Frunze, built by the Czechoslovak cooperative "Intergelpo." It is a pioneer of the textile industry in Kyrgyzstan. At that time, the factory was equipped with ten looms brought from Czechoslovakia. Its capacity in the first year was 400 spindles.

Currently, the Kyrgyz Woolen and Cloth Combine is one of the largest enterprises in the country, equipped with the latest technology. The first stage — cloth production (7,080 spindles), launched in 1963, almost surpassed the capacity of the K. Gotwald Woolen Factory by 7 times.

Ural, Volga Region, Central Asia — these are the addresses where Kyrgyz fabrics have found recognition.

The Frunze Sewing Factory named after the VLKSM is the only enterprise in Central Asia specializing in the production of men's, youth, and boys' suits. The factory began as a semi-artisanal workshop in the difficult 1930s for our country. This workshop had about thirty sewing machines of various brands, old and rickety.

At that time, it was the first state enterprise in Kyrgyzstan. Now the factory has become the leading enterprise of a whole sewing association. The tailors have the latest equipment, ensuring almost complete mechanization of production processes and the most modern technological schemes.

The dwellings of the Kyrgyz were previously yurts — lightweight portable structures made of quickly disassembled wooden frames covered with felt.

Let’s take a look inside a yurt. The furniture consisted of fur and felt carpets and various-sized bags and sacks in which clothes and utensils were stored. In the center of the yurt was a place for the hearth. To the right of the exit was the women's half, and to the left was the men's. Opposite the entrance, bedding, felt, and carpets were stacked. The corner of the upper felt could easily be lifted, allowing fresh air and sunlight to enter the inner space while the smoke from the fire escaped... That was how it was.

Housing construction is being carried out in unprecedented sizes in the republic today. In 1923, the housing stock in cities and workers' settlements amounted to 679,000 square meters. From 1925 to 1981, residential buildings with a total usable area of 35 million square meters were built in the republic. In the last quarter of a century, 2.8 million people, or 76% of the population of Kyrgyzstan, received new apartments or improved their living conditions.

The construction materials industry produces cement, precast concrete, and facing products (Kant Cement and Asbestos Plant, Tokmak Plant for Facing Materials, and others).

Industry of Kyrgyzstan