How I Became Disillusioned with Gold

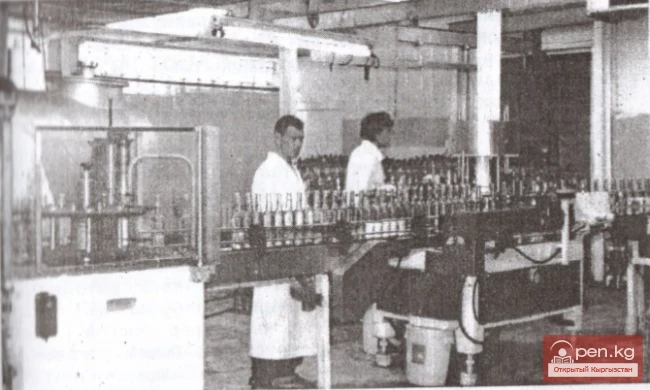

I am from Kara-Balta. For many years, I drove past the refinery and dreamed of visiting it. The dream came true: I saw with my own eyes how gold is produced. And at the same time, I debunked the myth that real ingots must be perfectly smooth and shiny.

It is here, in the industrial zone of Kara-Balta, that all the gold mined in the country is processed. The refinery is the only one in the republic.

Outsiders are not allowed into the factory. Even the mere fact that someone might wander in here by accident is excluded. At the entrance, we are greeted by the director, Vladimir Melnikov. He is the only employee allowed to be photographed. Showing the faces of others is prohibited for security reasons.

The refinery in Kara-Balta was built in 1992 by the efforts of the Kyrgyz State Mining Company (KGRK), based on a similar plant in Zarafshan (Uzbekistan). The technology was refined at the Central Scientific Research Laboratory (CSRL) under KGRK.

Vladimir Melnikov is the only employee allowed to be photographed

The plant was designed to process gold from the Makmal deposit. Due to the small volume of mining in the republic, it was designed to produce two tons of pure gold per year. Today, the main supplier of raw materials to the plant is "Kumtor." They bring in Dore alloy, consisting mainly of gold and silver, with 5-6 percent of various impurities—from copper to iron.

Come in, undress!

From the moment the Dore alloy is delivered to the plant until the finished refined ingot is obtained, it takes eight days. The process is not quick, and it cannot be accelerated. The director of the enterprise, Vladimir Melnikov, allowed us to enter the plant and showed how the process works.

According to the rules, employees cannot enter in their own clothes. They completely undress, are searched, and only then enter and change into work clothes inside.

This rule is uniform for all refineries. The enterprise is responsible for the safety of every gram of precious metal, and therefore security measures must be unprecedented.

An exception was made for the journalist. I did not have to show the security of the refinery how I looked in my underwear.

We were even allowed to bring in a notebook, pen, and camera—an unheard-of generosity. In the workshop where the stamping and weighing of ingots is done, photography had never been allowed before. However, we could not bring a cell phone past security, no matter how we asked. We had to accept that.

The refinery is the only one in the republic. Here, all the gold is processed

Every door here is locked, sealed, and alarmed. There are cameras everywhere. Yes, even where completely naked employees are searched.

So, we go through the search procedure. My nose, ears, and mouth are examined more thoroughly than by a doctor. But one thing is health, and quite another is to take even a gram of precious metal out of the plant. For that, one can receive a very real prison sentence.

Study Chemistry, You Underachievers!

The primary task of the plant is to separate gold and silver. Then, from the obtained unrefined products, refined gold and silver with a fineness of 999.9 are produced. The initial separation of gold and silver occurs using high-temperature chlorination, or the Miller process. After that, the refining of the obtained products—gold and silver—occurs through electrolysis.

How does the process of separating metals occur? There is nothing supernatural about it. Simple chemistry. Those who were even a little interested in the subject in school will understand the essence of the process.

The Dore alloy from the Kumtor deposit is placed in a crucible with a quartz tube

"So, how did you study chemistry in school? Do you know what electrolysis and chlorine are?"—Vladimir Nikolaevich asks me with a smile.

"I studied well. I definitely remember about chlorine and electrolysis,"—I timidly reply.

It turns out that the Dore alloy from the Kumtor deposit is placed in a crucible with a quartz tube. It is through this tube that gaseous chlorine is supplied. This gas reacts with all the impurities and silver. However, chlorine does not react with gold.

“Here’s your first lesson in chemistry. Impurities and silver form chloridic slags. This is how the initial separation of gold and silver with impurities occurs. The slags float to the surface, while the melt, containing about 96 percent gold, concentrates at the bottom.”

Vladimir Melnikov

From the primary refined gold, gold anodes are cast and hung in electrolysis. In the bath with liquid, plates hang. Under the influence of electricity, the anode dissolves, and chemically pure gold with the highest fineness of 999.9 is deposited on the cathode plate.

The ingots are small, but they are substantial in weight—on average, 12.5 kilograms

"The gold precipitate is compact and dense. It is scraped off with a special scraper. The process of obtaining gold and silver is the same. But during electrolysis, they behave differently. Silver precipitates as a fine crystalline sediment. It even falls to the bottom of the electrolyzer,"—Vladimir Melnikov explains.

Everything Shines and Glitters

Have you ever seen what unrefined silver of the highest fineness looks like? I saw it for the first time at the refinery. The sight is simply mesmerizing. Such sparkle probably doesn’t exist anywhere else. It’s a pity you can’t touch it.

It turns out that after the separation of gold and silver in the crucible, the resulting slags are processed to obtain silver. All harmful impurities from the slags are separated, and then the silver-containing slags are reduced with soda, melted in furnaces, and metallic silver is obtained. The process is then similar to that of gold—anodes are made and hung in another separate room for electrolysis.

The process of obtaining refined gold and silver from Dore ingots takes eight days, regardless of the volume of metal. This is due to the large number of preliminary procedures.

“Everything needs to be weighed carefully to the accuracy of one-tenth of a gram, then all the waste must be processed. But we also have a high speed of electrolysis. In other plants, it can be significantly longer—two or three weeks,”—the director admits.

Control and Analysis at Every Stage

The plant also has its own laboratory. It is here that the product is studied at every stage of refining.

In the laboratory, the content of gold and silver in the ingots is determined. Here, a complete breakdown is provided of what impurities are included in the composition, how many harmful substances are in each ingot.

The Main Disappointment

For me, probably like for most girls, the main highlight was the workshop where the stamping and weighing of finished refined ingots is done. They not only let me in there with a camera but even allowed me to touch the very gold that is obtained from the Dore ingots from Kumtor.

The unpresentable appearance of the ingots indicates that this is a real quality product

And here I encountered perhaps the biggest disappointment of the day. The finished refined ingot looks nothing like we imagine and how it is shown in the movies. It is uneven and unpolished. Honestly, I initially thought that I was shown still unfinished ingots. But for some reason, they had a stamp, number, and fineness on them.

It turned out that these inconspicuous ingots are indeed the real ones. And their unpresentable appearance indicates that this is a genuine quality product. No one will grind or polish them. That’s the rule.

“According to the conditions of the London Stock Exchange, a gold ingot obtained by casting should not bear traces of mechanical processing. This is done to avoid the risk of counterfeiting, where a foreign substance is embedded in the ingot, then covered with gold and polished, while inside there is a hollow core. The absence of any processing is a guarantee that the ingot is indeed gold,”—the specialists explain, seeing my reaction.

There was a case when tungsten inserts were found inside ingots on the Chinese exchange.

Interestingly, the weight is never indicated on the ingot. The reason is simple—during transportation, part of it may wear off, and when reweighed, the weight may turn out to be quite different. And that would be a real scandal.

I was also allowed to touch those very ingots. However, with my manicure, I almost caused the employees of the plant to faint when I tried to lift the largest one.

“Miss, be careful!!!”—several people exclaimed in unison as soon as I tried to lift the ingot. I was surprised: what’s the problem? I won’t break it.

“What do you mean? It’s heavy, even though it’s not very big, and you can easily scratch it,”—they immediately replied.

What a surprise! The gold of the highest fineness of 999.9 produced here is very soft. Even a small impact can damage it. One awkward move—and I could have scratched the finished stamped ingot with my nail, completely ruining it. And it costs several tens of millions of soms.

It’s small, but the ingot has a significant weight—on average, 12.5 kilograms. No matter how much I love gold, this piece turned out to be too heavy for me. After lifting it just a couple of centimeters, I honestly admitted amidst the laughter of the employees that I couldn’t carry such a piece. What a pity, such a pity!

No Harm to the Environment

When I first heard that chlorine is used in the process of separating gold and silver, I thought that all employees walk around in what could be described as spacesuits. At the very least, they wear respirators because it must be impossible to breathe.

That was not the case. The smell, of course, is not the most pleasant, but it cannot be called suffocating. It turns out that the plant has a special gas purification system. It operates with an efficiency of 99 percent.

“We can confidently say that we cause virtually no harm to the environment. But our system solves two tasks. It not only cares for the ecology of the city of Kara-Balta but also prevents precious metal from evaporating,”—Vladimir Melnikov said.

Cast Ingots and Graphite Molds

In addition to the main work of processing gold supplied by "Kumtor Operating Company," the refinery also works with private companies that develop small deposits and bring in tailings obtained by washing gold-containing sands for processing. Contracts have been signed with "Altynken" and "Full Gold Mining."

“We also work with the National Bank. At its request, we certify the gold that the regulator purchases from companies. We test it and put our stamp on it. It is registered on the London Metal Exchange. The so-called concept of Good Delivery—good supplier. Gold with our stamp is not tested anywhere else in the world.”

Vladimir Melnikov

The quality of gold in the finished ingots is determined at the Central Scientific Research Laboratory (CSRL), which is part of KGRK. In March 1998, this laboratory received accreditation from the National British Accreditation Service (UKAS) to conduct analytical analyses of Dore alloy and to certify ingots: gold in ingots—fineness 999.9, silver—999.

The products of the plant are standard bank ingots (each weighing approximately 12.5 kilograms) and silver ingots weighing 25 kilograms, as well as one-kilogram and 100-gram ingots.

Ingots weighing from one to 70 grams are made only by stamping. A normal ingot is obtained by casting from 70 grams and above.

For the production of those very 100-gram ingots of the National Bank, which are the most popular, a separate room has been allocated. In special graphite cells—molds—gold is mixed with sand. Then it is melted and cooled.

Next, the stamp is carefully applied to the finished ingots so as not to damage the product. On ingots weighing 1 kilogram and 100 grams, in addition to the "Kyrgyzaltyn" stamp, the fineness and weight must also be indicated.

To exit the room where gold refining and ingot production takes place, we go through a thorough search again. And this is despite the fact that we were accompanied by employees of the enterprise who monitored every step and movement.

We exited, and the solid metal door behind us slammed shut with a crash, locking all the bolts and activating the alarm. The process of making gold from inconspicuous Dore ingots continues.

Tatyana Kudryavtseva