The Textile Industry of Pakistan Faces Rising Costs and Logistics Disruptions

In Pakistan, the textile industry, which plays a crucial role in the country's economy, is facing serious difficulties. Rising production costs, a decline in export volumes, and disruptions in supply chains, exacerbated by a nationwide strike of transporters, are putting significant pressure on this sector.

According to the Pakistan Textile Exporters Association (PTEA), the sector, which traditionally provides a substantial portion of export revenues and employment, has shown a decline in export volumes for the fourth consecutive month. This is raising growing concerns among market participants about the future of the industry.

PTEA notes that exports in the 2021 financial year amounted to $19.3 billion; however, in the following years, this figure dropped to $18 billion and then to $17 billion. From July to November 2025, exports fell by 6.39%, decreasing from $13.721 billion to $12.844 billion, indicating ongoing pressure on external supplies.

Despite having manufacturing resources and stable demand for textiles in some foreign markets, such as North America, Pakistani manufacturers are facing rising energy costs, high tax burdens, and increased financing costs. These factors negatively impact the competitiveness of Pakistani textiles compared to goods from Bangladesh, India, China, and Vietnam.

The situation in the cotton sector is also worsening the situation. Cotton production is declining due to agronomic and climatic issues, leading to the closure of several spinning and cotton ginning factories. Experts estimate that cotton production has fallen from 15 million to 5.5 million bales, which in turn affects the entire processing chain.

Changes in export regulations are also drawing attention, including adjustments to the Export Facilitation Scheme (EFS) and increased taxes on raw materials. These measures, according to the business community, negatively affect the liquidity of companies and their cost structure. Additionally, issues related to the influx of imported yarn and price competition in the domestic market remain relevant.

Energy tariffs remain a significant pressure factor on the sector. It is expected that in the coming years, the cost of electricity for industry will rise to 12 cents per kWh, which is significantly higher than in some neighboring countries. Power outages also threaten the stability of production processes.

On international markets, Pakistani manufacturers face various tariff and non-tariff barriers. In particular, exports to the USA are subject to higher duties compared to competitors in the region. Nevertheless, the export geography remains quite narrow: the European Union continues to be the largest market, while supply volumes to the USA have remained virtually unchanged for several years.

The nationwide strike of transporters has further exacerbated the situation, halting logistics operations and delaying export shipments. Experts estimate that daily losses could reach tens of millions of dollars, and logistics disruptions affect a wide range of export-oriented companies.

Market participants acknowledge that the further sustainability of the textile sector depends on a set of measures aimed at reducing costs, supporting raw material production, stabilizing logistics, and ensuring predictability in economic policy. In the context of ongoing uncertainty, the industry is forced to adapt to new internal and external challenges.

Source: https://www.dailymirror.lk/international/Pakistans-textile-industry-reels-under-rising-costs-and-supply-chain-disruptions/107-328825

Read also:

Indian exports reached a record in the first half of 2026.

India is not only participating in global trade but also actively shaping its future. India's...

The trade turnover of Kyrgyzstan decreased by $1 billion due to a drop in exports.

From January to September 2025, the volume of foreign trade in Kyrgyzstan reached $11 billion...

China's Trade Surplus Exceeds $1 Trillion for the First Time

China has reached an important milestone in its trade: according to the country's General...

Exports are falling, prices are rising. What is happening with Kyrgyzstan's economy?

According to official information, the gross domestic product (GDP) of Kyrgyzstan shows steady...

Kyrgyzstan Significantly Reduced Foreign Trade

According to data from the Ministry of Economy, from January to September of the current year, the...

Kyrgyzstan Increases Production of Construction Materials, Pharmaceuticals, and Food Products in 9 Months

- According to data from the Ministry of Economy and Commerce, the gross output produced by...

Kyrgyzstan's Trade Decreased to $12.8 Billion: Exports Down Nearly 40 Percent

According to data from the National Statistical Committee of Kyrgyzstan, the volume of foreign...

Exports from India are growing again. The government supported companies with a $5 billion package of measures.

The restored growth of Indian exports enters a new, significant phase characterized by confidence...

Kyrgyzstan Shifts Coal Export Vector from China to Uzbekistan

The energy market in China is undergoing changes One of the most noticeable geo-economic phenomena...

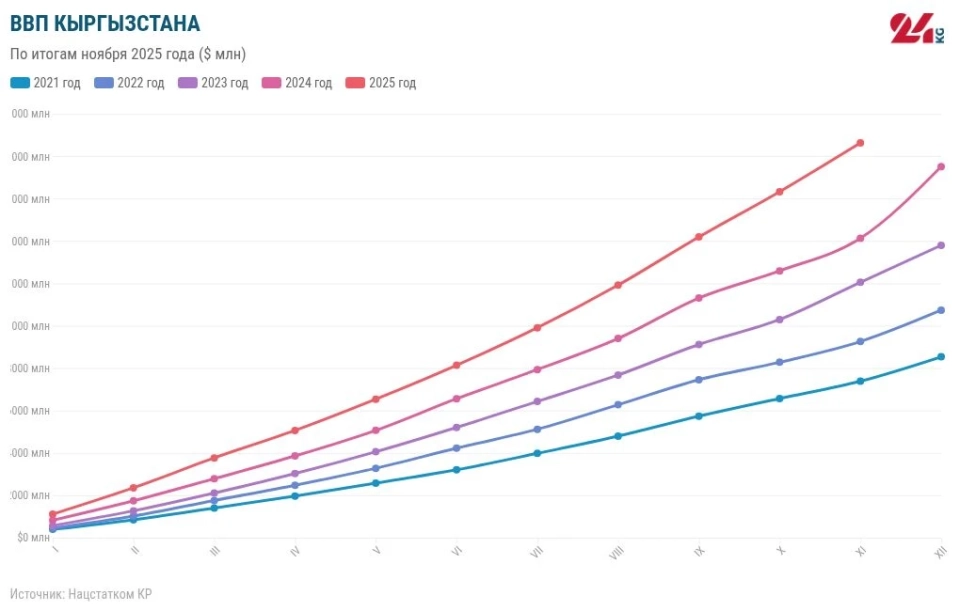

GDP of Kyrgyzstan from January to November 2025 compared to the same period in 2024 increased by 10%

The total estimate of the gross domestic product for January-November 2025 amounted to 1 trillion...

The foreign trade turnover of Kyrgyzstan since the beginning of the year amounted to $11.3 billion

From January to September 2025, the external trade turnover of the Kyrgyz Republic amounted to...

The GDP Growth of Bangladesh is Accompanied by Challenges in the Financial Sector

The economic situation in Bangladesh evokes mixed feelings. On one hand, the government emphasizes...

Kyrgyzstan Becomes the Main Exporter of Used Cars from South Korea

During the same period, Kyrgyzstan imported cars worth 2.6 billion dollars, while Russia and...

Kyrgyzstan entered the top 20 in the number of cars imported from China

According to the General Administration of Customs of China, Kyrgyzstan ranked 20th in the number...

Kyrgyzstan Ranks 3rd in the List of Countries Importing Agricultural Products from Russia in the EAEU

In the first nine months of 2025, Russian exports to the EAEU countries exceeded $6 billion,...

China is displacing Russia from Mongolian exports — intelligence

In 2023, Mongolia plans to increase coal exports to China by nearly 20%. It is expected that the...

Gas supplies from Russia to Kyrgyzstan are planned to be increased by 2 times

Growth in fuel exports is also expected to other Central Asian countries According to a report...

In 5 years, the volume of industrial production in Kyrgyzstan has increased by 23%

- According to data from the National Statistical Committee, the volume of industrial production in...

Central Asia Shows Rapid Growth in Intra-Regional Investments - EDB

According to the Eurasian Development Bank, in 2023, intra-regional investments in Central Asia...

Kyrgyzstan Increased Butter Exports Abroad

According to the National Statistics Committee, from January to September, Kyrgyzstan increased its...

"Gazprom Plans to Significantly Increase Natural Gas Supplies to Kazakhstan, Kyrgyzstan, and Uzbekistan"

The company "Gazprom" plans to significantly increase the volumes of natural gas...

In 3 years, the volume of loans issued to women entrepreneurs increased from 23.6 to 34.5 billion soms

- From January to June 2025, the government allocated 98.8 billion soms for loans, with 34.5...

In Kyrgyzstan, the volume of pension financing amounted to 96.1 billion soms

According to preliminary data, from January to November 2023, pension funding in Kyrgyzstan...

"Gazprom Increased Gas Supplies to Kyrgyzstan by 20 Percent in 2025"

The head of Gazprom, Alexey Miller, announced the company's plans to increase gas supplies to...

Pakistan Faces Management Challenges in the Healthcare System

The regular change of leadership in the Ministry of Health causes instability The problems in...

Global Food Price Index Declines for the Third Consecutive Month - FAO

In November 2025, global prices for key food products continued to decline, with the exception of...

Since the beginning of the year, potato exports to Uzbekistan have decreased by 50%.

- According to the National Statistical Committee, from January to October 2025, potato exports to...

Russia increased gas exports to Kyrgyzstan, Kazakhstan, and Uzbekistan by 15%

The increase in gas exports is also related to the planned construction of the main gas pipeline...

National Statistical Committee of Kyrgyzstan: The Republic Maintains a Positive Trend in Economic Growth

Analysis shows that the growth of industrial production during the specified period was driven by...

The Tax Service replenished the budget by almost 19.5 billion soms from excise duties

In the course of 11 months of the current year, the budget of Kyrgyzstan received 19 billion 493.06...

The volume of Kyrgyzstan's foreign trade decreased by 8.3%

According to the National Statistical Committee, in the first nine months of 2025, the volume of...

Sadyr Japarov stated that Kyrgyzstan has reduced the volume of debt in the energy sector by five times. How?

In an interview with the "Kabar" agency, President Sadyr Japarov commented on the current...

In 2025, taxes from the mining industry increased by 18.7 billion soms

In the course of 11 months of 2025, key sectors of the economy significantly increased their tax...

The Industry of Kyrgyzstan Grew in Almost All Regions: Chui is the Leader, Issyk-Kul Declined Due to Kumtor - Chart

- According to information from the National Statistical Committee, from January to October 2025,...

Industrial production in the Kyrgyz Republic grew by 10% over 11 months, reaching 686 billion soms

- According to the data from the Ministry of Economy and Commerce, from January to November 2025,...

In Kyrgyzstan, the production of bakery products and pastries exceeded 18 billion soms in 11 months

- From January to November 2025, the production of bakery products and pastries in Kyrgyzstan...

"Kyrgyzkomur" exported about 30% of the coal mined since the beginning of 2025

Decrease in coal production volumes in 2025 Since the beginning of this year, «Kyrgyzkomur» has...

Will Prices Continue to Rise? What is Happening with Kyrgyzstan's Economy

The gross domestic product (GDP) shows impressive growth. How do the authorities explain the...

The Industry of Kyrgyzstan Maintains Investment Attractiveness Due to Raw Material Sectors, - Ministry of Economy

According to the project of the Strategy for the Development of Industry in Kyrgyzstan until 2030,...

Islamic financing in banks increased by 91.5%. The largest volumes were in mortgages.

- As of October 31, the amount of financing conducted in accordance with Islamic principles in the...

Inflation Catches Up with Economic Growth in Kyrgyzstan: Results of 11 Months of 2025

According to preliminary data, the gross domestic product of Kyrgyzstan from January to November...

There is a structural shortage of quality warehouse real estate in the Eurasian region, - EDB

- The analysis of warehouse real estate in the Eurasian region was presented by EDB analysts on...

Bicycle Tourism Routes by Difficulty Categories

2 difficulty categories...