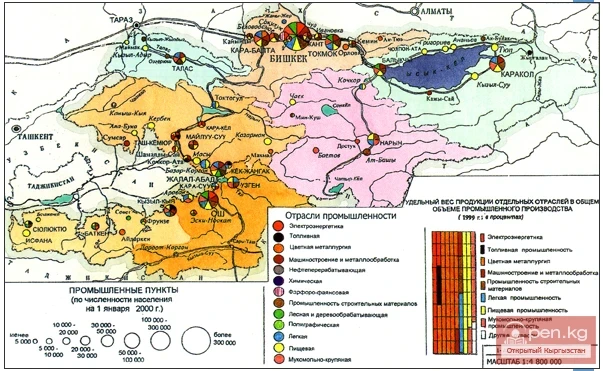

Development of the Mining Industry in Kyrgyzstan

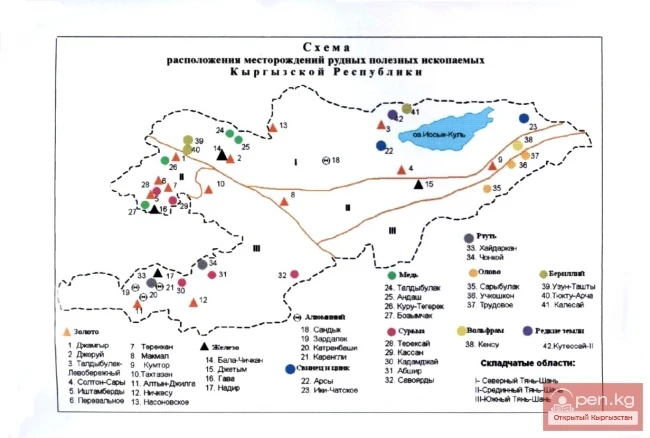

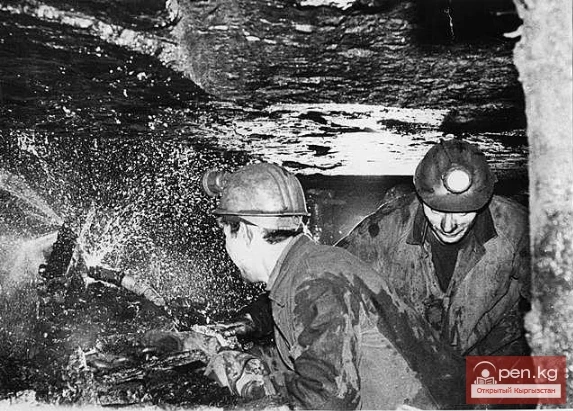

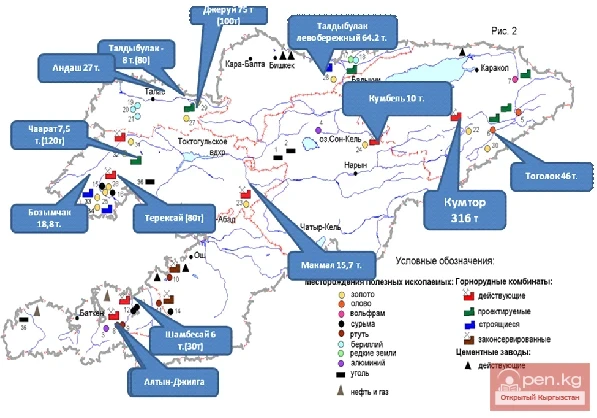

Kyrgyzstan has deep traditions in the exploration of mineral resources. As early as the beginning of the 20th century, industries for coal, oil, lead, mercury, antimony, and copper were operational. During World War II, more than 20 enterprises were engaged in the extraction of lead, antimony, mercury, gold, tungsten, arsenic, and coal. Later, the mining and metallurgy sector of Kyrgyzstan played a significant role in the raw material economy of the USSR. The share of mineral product production at certain periods was 15-18% for lead, 40-100% for mercury, 100% for antimony, up to 30% for rare earth metals, and up to 15% for uranium.

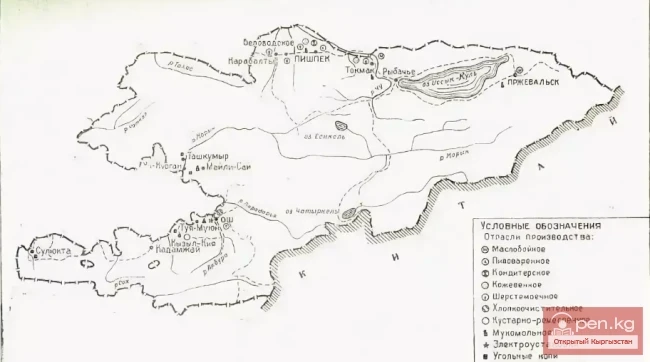

In the 1980s, the extraction of non-metallic raw materials for the production of construction and structural materials developed successfully, fully meeting the needs of the country's construction industry and supplying neighboring Soviet republics, including cement (over 1 million tons per year), bricks, stone casting, and facing materials. Stone and metal processing capacities were put into operation. For the first time, mechanized devices designed for bending steel, aluminum, copper, and PVC pipes—pipe benders—were introduced. The use of pipe benders in production significantly facilitated the process of installing water supply, gas supply, sewage systems, and laying cable systems.

In the second half of the 19th century, the first coal enterprises appeared in the south of the country. By 1913, there were 27 coal mines operating with a total output of about 100 thousand tons of coal per year, supplying almost all of Central Asia. In the 1940s-60s, coal was extracted from 7 mines and 5 open-pit mines, reaching a maximum of 4.9 million tons in 1979. The Republic consumes about 1.9 million tons of coal annually, supported by the World Bank's Grant for capacity building in management and administration of revenue in the mining industry and natural resource sector, but its extraction fell to 0.495 million tons in 2004 due to the depletion of deposits and low production profitability.

From other non-metallic minerals, since 1968, the Kyrgyz Republic has produced fluorite concentrate. A total of 200 thousand tons of product was obtained, with maximum production in 1971 being 14,500 tons. Up to 50 thousand tons of barite were produced at the Kyrgyz Mining and Metallurgical Company from imported raw materials supplied from Kazakhstan, but with the collapse of the USSR, the raw material base was lost.

Starting in 1987, the mining and metallurgy sector grew faster than the economy of Kyrgyzstan as a whole, thanks to significant investments in several enterprises (Kyrgyz Mining and Metallurgical Company, Kyrgyz Chemical and Metallurgical Plant, Sary-Jaz Tin Plant). By the end of the 1980s, Kyrgyzstan produced 100% of the USSR's antimony, up to 64% of mercury, up to 30% of rare earth products, and up to 15% of uranium.

Up to 50 million rubles were invested annually in the search and exploration of mineral resources. About 50 thousand people were employed in the mining and metallurgy industry, and up to 11 thousand people were engaged in the search and exploration of deposits.

Since 1993, there has been an influx of foreign capital into Kyrgyzstan's gold mining industry. In 1996, in partnership with the Canadian corporation "Cameco," the world-class Kumtor deposit with reserves of over 300 tons of metal and a production capacity of over 650 thousand ounces of gold per year was put into operation. Two more deposits with geological reserves of 65-70 tons are prepared for development.

Private firms are extracting tin in small volumes.

Since 1900, exploratory work has been conducted for oil. By 1913, oil production reached 3,000 tons. Currently, 7 oil and gas fields are being developed. Oil production has fallen from 490 thousand tons in 1958 to about 73.3 thousand tons in 2004 (3.7% of demand). Gas production has decreased more than tenfold, amounting to 32.2 million cubic meters in 2000 and 28.1 million cubic meters in 2004 (3% of demand).

The extraction and bottling of mineral and drinking water from wells has developed. More than twenty enterprises for bottling mineral and drinking water with mixed capital have been established.

In recent years, individual extraction of placer and lode gold has become widespread, employing up to 5 thousand people.

Thus, the Kyrgyz Republic has extensive experience in mineral extraction and sufficiently qualified hereditary personnel.

Kadamjay Antimony Plant (KSP) accounted for about 15% of the world's antimony production. In 1990, Kyrgyzstan produced 17,608 tons of antimony, ranking 3rd in the world after China and Bolivia. Currently, KSP has completed the operation of its own deposits and mainly works with imported raw materials.

Haydarkhan Mercury Plant (HMP) operates at the largest antimony-mercury deposit in the world (after Almaden, Spain) and has been in operation for 70 years. From 1940 to the present, about 45 thousand tons of mercury have been extracted. Metal production reached 793 tons in 1989, accounting for more than 1/4 of world production. Currently, Kyrgyzstan is the third-largest producer of mercury in the world.

Kara-Balta Mining and Processing Plant (KBMPP) was built in 1951 as a uranium processing plant. It has worked six uranium deposits, two of which are located in Kyrgyzstan and four in Kazakhstan. Then the raw material base completely moved to Kazakhstan, and with the collapse of the USSR, it was lost. The plant provided up to 20% of the USSR's uranium production.

The production capacity of KBMPP is 1.5 million tons of ore per year and 2.5 thousand tons of products. The plant also produced by-products of molybdenum, tungsten, rhenium, and in recent years refined up to 25 tons of gold and silver per year.

During World War II (1942), the Kyrgyz Mining and Metallurgical Plant (KGMP) (now Kyrgyz Chemical and Metallurgical Plant) began operations at the lead deposits of Aktyuz and Boordu. Since 1962, the extraction of rare earth ores began at the Aktyuz-Kutessai II deposit. The plant produced 14 rare earth elements in the form of metals, salts, ligatures, and phosphors.

The production capacity is 600-800 tons of products per year. Currently, the extraction of rare earth ores has ceased.

In 1986, the Makmal Gold Mining Plant was built. Since then, the history of industrial gold production in Kyrgyzstan began.

Read also:

Kazakhstan Resumed Coal Supplies to Kyrgyzstan

In the coming days, the republic will receive about 424 thousand tons of Kazakh coal About 15 days...

Brown coal production increased by 23.7% over 8 months, reaching 2.04 million tons

- From January to August 2025, various dynamics in coal production were observed in Kyrgyzstan....

Hydrocarbon Resources

The territory of the republic has discovered deposits of coal, gas, and oil. Among them, coal...

Fuel Industry

The Republic has a significant amount of diverse fuel and energy resources. Involving them in...

Coal Mining in Kyrgyzstan in the First Half of the Great Patriotic War

Emergency measures were taken to increase the extraction of fuel, primarily coal. Assessing the...

In Kyrgyzstan, the production of key types of construction materials has increased by an average of 50%

- From January to August 2025, there has been an increase in the extraction of key construction...

Oil and Natural Gas Production in Kyrgyzstan Decreased by an Average of 9%

- From January to August 2025, Kyrgyzstan registered a decrease in oil and natural gas production...

Mining Complex

The traces of ancient mining operations in the territory of Kyrgyzstan indicate that mercury,...

Project of Construction of CHPP-5: An Innovative Path to Energy Independence and Environmental Safety

The TPP-5 project aims to reduce dependence on electricity imported from abroad and increase...

The Industry of Kyrgyzstan within the Russian Empire

The Industry of Kyrgyzstan in the Territory of Turkestan In the early 1890s, intensive exploration...

Everything for the Front: Oil and Coal Extraction in Kyrgyzstan

The war exacerbated the situation regarding the supply of oil to the country's industry and...

Natural Resources of the Kyrgyz in the 18th - Early 20th Century

Even during the time of the Kokand Khanate, the wealth of the subsoil of Kyrgyzstan was well...

The flour supplies in Kyrgyzstan will last until spring.

In 2017, wheat harvest in Kyrgyzstan reached 665 thousand tons. Thanks to this, the flour reserves...

The City of Kyok-Dzhangak

City of Kök-Jangak (Kyrgyz: Көк-Жаңгак) — a city of regional subordination in the Jalal-Abad...

Mines of the Kyrgyz Republic

Kumtor Deposit is a unique site developed by the Canadian company "Centerra Gold Inc.",...

The Industry of Kyrgyzstan

The development of Kyrgyzstan's industry began even before the October Revolution. In 1913,...

In the Kyrgyz Republic, the yield of certain crops in 2025 decreased due to a lack of irrigation water, - Ministry of Economy

- In the first nine months of 2025, the gross agricultural output of the country reached 348.4...

Natural Resources in 1917-1991

Kyrgyzstan is rich in natural resources, with rare metal deposits of gold and sulfur-containing...

Ready for the heating season!

The First Deputy Prime Minister of the Kyrgyz Republic, Taiyrbek Sarpashev, held a meeting with...

In Bishkek, measures to reduce air pollution during the autumn-winter period were discussed

The data provided by international organizations such as UNEP, UNDP, UNICEF, the International...

Tash-Kumyr

The first settlements in the current location of the city of Tashkumyr appeared during the...

The State of the Environment in the Kyrgyz Republic in 2008-2012.

As of January 1, 2013, the territory of the Kyrgyz Republic, according to the State Registration...

Coal

Coal deposits in the republic are grouped into 4 basins (Southern Fergana, Uzgen, Northern...

Issyk-Kul residents held a cleanup in the Kurchin Gorge, removing over 3 tons of waste.

In the Issyk-Kul region, a clean-up was held in the Kychyn gorge, where over 3 tons of garbage...

In a year, flour production increased by 8%, totaling 182.3 thousand tons

- From January to August 2025, Kyrgyzstan recorded an increase in the production volumes of several...

Production of Livestock Products as of March 1, 2015

Meat Production. During the reporting period of 2015, economic entities of all categories in the...

Illegal import of fuel and lubricants from Kazakhstan reaches tens of thousands of tons.

On October 8, this was stated by the Minister of Economy of Kyrgyzstan, Oleg Pankratov, at a press...

The Government of the Kyrgyz Republic Introduces State Price Regulation on Coal

In order to control the price situation in the coal extraction and sales market, to curb price...

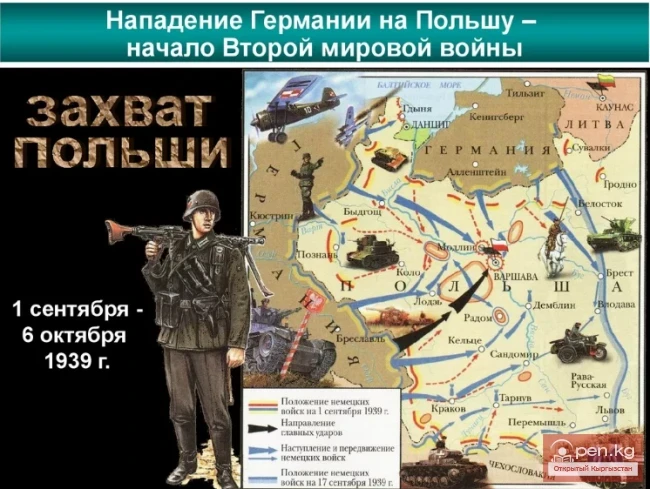

The Beginning of World War II

The Attack of Nazi Germany on Poland. On September 1, 1939, Nazi Germany attacked Poland. Two days...

In Kyrgyzstan, the State Balance accounts for reserves from over 1000 deposits of 51 types of minerals.

As of today, Kyrgyzstan has registered reserves of more than 1,000 deposits belonging to 51 types...

Volume of Industry for the First Half of 2014

In the first half of 2014, industrial enterprises produced goods worth 65,851.3 million soms, with...

Building Materials

Before 1917, there were 6 semi-artisanal brick factories in Kyrgyzstan, mostly operating...

The Economy of the Kyrgyz in the USSR (1917-1991)

The situation in Kyrgyzstan by the end of the Civil War was very difficult. In 1922, industrial...

Sartova Kulumkan Abdykerimovna

Sartova Kulumkan Abdykerimovna Candidate of Chemical Sciences, Associate Professor. Born in 1952....

Woodworking Industry

The share of the forest, woodworking, and pulp and paper industry of the republic in 2000 was: by...

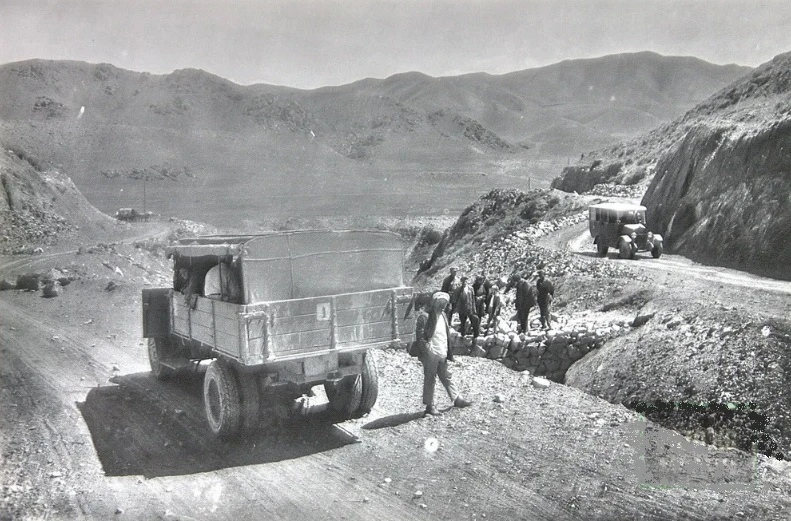

Railway, Road, and Water Transport of the Kyrgyz SSR in the Early Years of World War II

The various types of transport in the republic that grew during the years of Soviet power—railway,...

Mineral Resources and Other Resources of Kyrgyzstan

People's Experience in Using Natural Resources. The republic has reserves of fossil fuels,...

Metallurgy of Kyrgyzstan

Ancient Metallurgy. The mastery of metal smelting in human history was a great discovery that led...

Kyrgyzstan Increases Production of Construction Materials, Pharmaceuticals, and Food Products in 9 Months

- According to data from the Ministry of Economy and Commerce, the gross output produced by...

Mineralogy and Mining

The forge of the zergers. Mid-19th century. The photo is kept in the State Historical Museum...

The Role of First Secretaries in the Development of the City of Osh

Creation of the Construction Industry Base in Osh Of course, the development of the city of Osh...

Liu Jiangping: A Thousand Chinese Buses Are Already Helping Bishkek Breathe Easier

At the national multilateral dialogue "Combating Transport Air Pollution in Kyrgyzstan:...

Industrial Steps of the Republic of Kyrgyzstan

Industry in Kyrgyzstan The leading sector of the national economy of the Kyrgyz SSR became...

Construction of Sewage System in Frunze. Document No. 143 (1943)

RESOLUTION OF THE COUNCIL OF PEOPLE'S COMMISSARS OF THE KYRGYZ SSR AND THE CENTRAL COMMITTEE...

Reconstruction of Industry and Transport in Kyrgyzstan for Military Purposes

Everything for the Defeat of Fascist Aggressors From the very first days of the war, the efforts...

Kyrgyz Republic

KYRGYZSTAN. Kyrgyz Republic A country in the northeast of Central Asia. Located within the...

Light Industry

The light industry of Kyrgyzstan encompasses its three sectors: textile, garment, and...

The Geopolitical Environment of the Kyrgyz Before the 6th Century

Since the Sakas did not have a centralized state, they did not conduct a specific foreign policy....