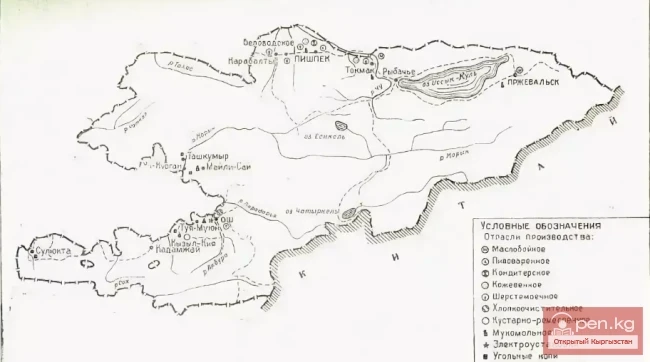

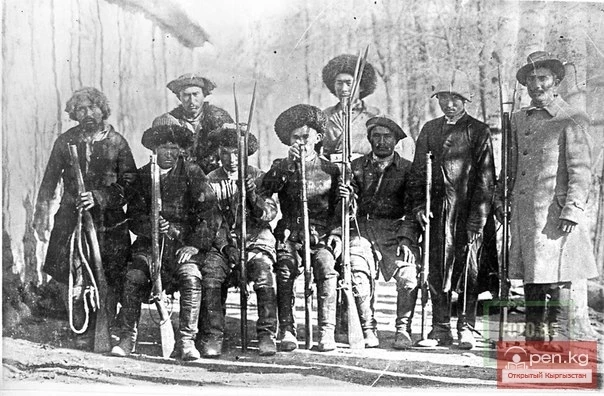

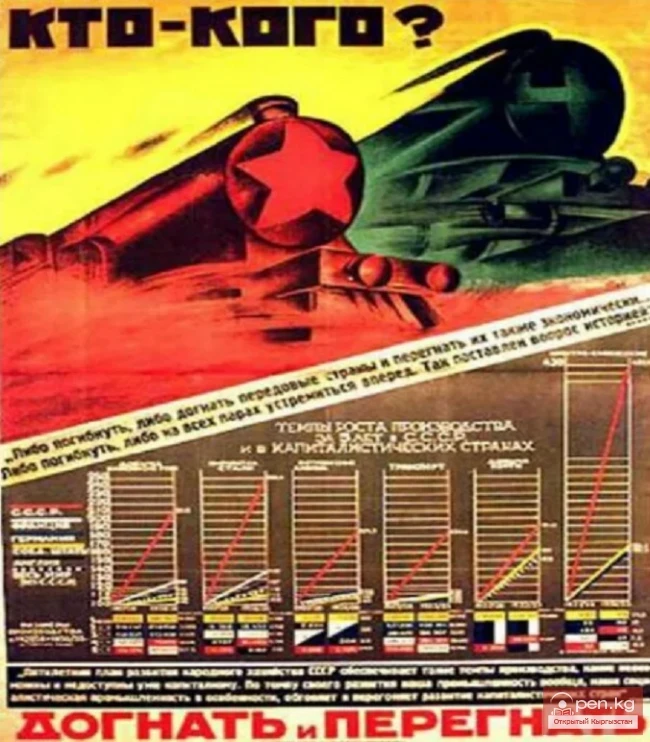

The development of Kyrgyzstan's industry began even before the October Revolution. In 1913, the share of industrial production was 3%. Before the revolution, compared to Russia, industrial output per capita in Kyrgyzstan was 16 times lower. The industry, based on artisanal production, was engaged in the processing of agricultural raw materials (86.5% of total industrial output). Before the revolution, there was 1 artisanal candy factory, 2 breweries, and 2 tanneries operating in Kyrgyzstan, as well as a workshop for producing fruit and berry juices, 11 mills, oil presses, and others. The total value of gross output produced by these enterprises amounted to 175 thousand rubles, and the number of workers reached only 150 people. There were several private enterprises for processing agricultural raw materials in the region, including primary wool processing and cotton cleaning enterprises. Five small state power plants operated with a total capacity of 265 kW. The mining and metallurgical industry was represented by several private enterprises engaged in the extraction of gold, ozokerite, and iron vitriol.

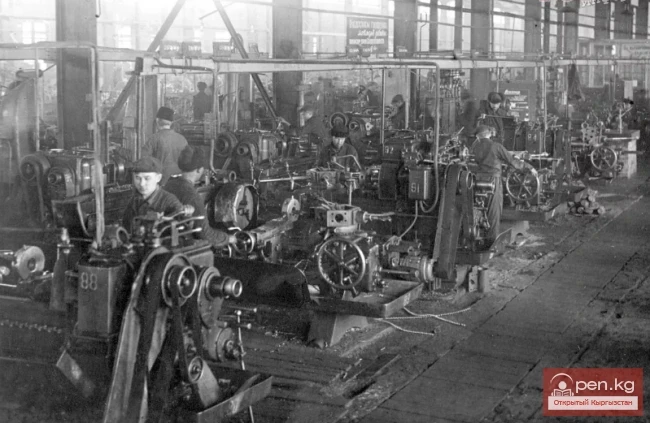

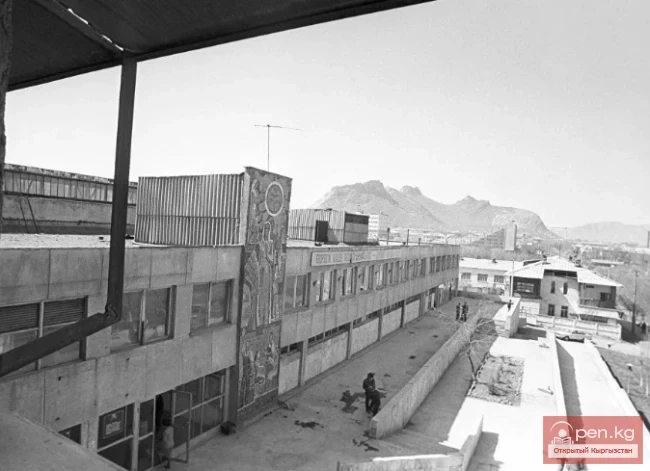

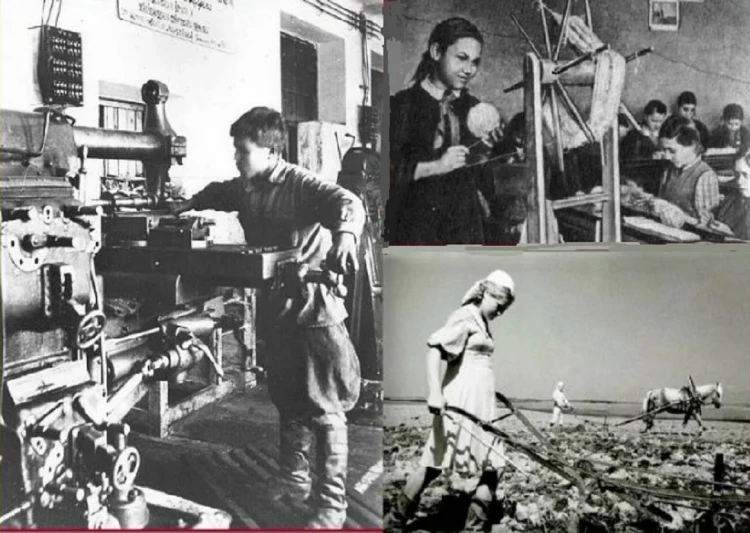

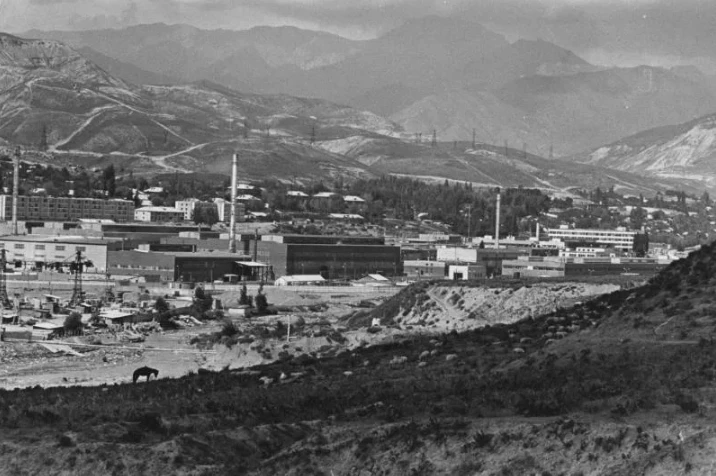

Mineral resources were not explored and were used haphazardly. There were 6 temporarily functioning brick factories and 1 lime factory in the country. In the fuel industry, 27 coal mines were developed (871 workers), and 2 oil fields employed (55 people). These enterprises accounted for 59% of the workers in the region and 50% of the output. After the October Revolution, the construction of the national economy began with the development of industry. The construction of large industrial facilities, rational use of rich natural resources, improvement of transport links, and development of labor resources created all the necessary prerequisites and conditions for the accelerated development of industrial production. From 1913 to 1981, industrial output increased 379 times. From 1940 to 1980, the average annual growth of industrial gross output in the republic was 10.2%. In 1980, industry accounted for 55.6% of the republic's gross social product. The industry of the republic as a whole consisted of 130 branches and sub-branches. In these branches, the produced output regularly increased. For example, in the machine engineering sector alone, more than 200 types of products were manufactured. The development of industry in Kyrgyzstan created favorable conditions for the development of the labor market. In 1980, the number of workers in the republic reached 197 thousand (compared to 2.5 thousand in 1913). Among those employed in the national economy, specialists with higher education made up 11%, while workers with secondary vocational education working in industry accounted for 20%.

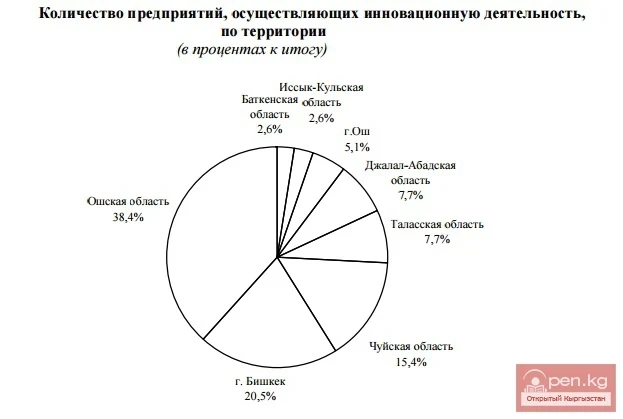

In recent years, as a result of the reorientation of industry to the requirements of market relations in the field of industrial production, significant sectoral changes have occurred. In this regard, in the republic, since 1991, necessary measures have been taken to create a market atmosphere — large enterprises were sold after restructuring and privatized. From 1992 to 1995, large-scale privatization took place in industry: in 1991 - 9, in 1992 - 108, in 1993 - 146, in 1994 - 59, in 1995 - 138, in 1996 - 22, in 1997 - 45, in 1998 - 3, and in 1999 - 4 industrial enterprises. Privatization was carried out without the appropriate preparation for working in market conditions, so many highly specialized enterprises halted production, some of them reprofiled to produce simpler products, and others are at risk of bankruptcy and liquidation. The output of industrial products from 1991 to 1995 decreased annually, and in 1995, compared to 1990, it fell to 32.8%.

The decline in production occurred across all major industries. The sequentially conducted market transformations in the economy have allowed for some improvement in the situation in industry at present. After 1995, a trend of production growth in industry emerged due to the attraction of significant foreign investments in non-ferrous metallurgy, fuel, and food industries.

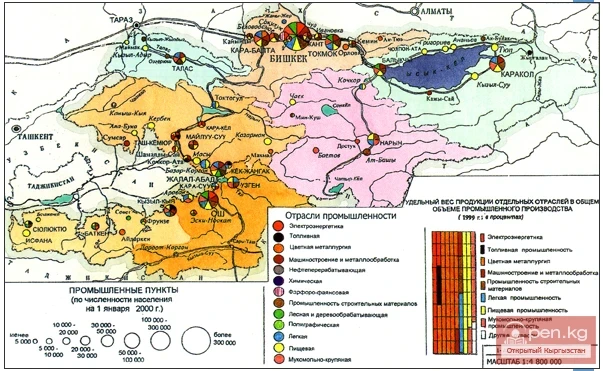

From 1996 to 2000, industrial production increased annually. In 1996, it was 32.8% (compared to 1990), and in 2000 — 62.4%. For all raw material industries, the production level in 2000, compared to 1990, was higher than the overall industrial level, accounting for 74.8% in the fuel sector, and 532.6% and 114.4% in non-ferrous metallurgy and electric power, respectively (above the 1990 level). The sharp increase in production in non-ferrous metallurgy is associated with the commissioning of the Kum-Tör gold mining enterprise in 1977. Along with the increase in the share of raw material sectors, there was a significant reduction in the share of processing and manufacturing sectors, which in 2000 (compared to 1990) accounted for 16.6% in machine engineering and metalworking, 30.1% in light industry, and 18.0% in the food industry.

Due to changes in consumer demand, difficulties in material and technical supply, sales of finished products, and the difficult financial situation of industrial enterprises, the share of previously large sectors — machine engineering and light industry — has decreased.

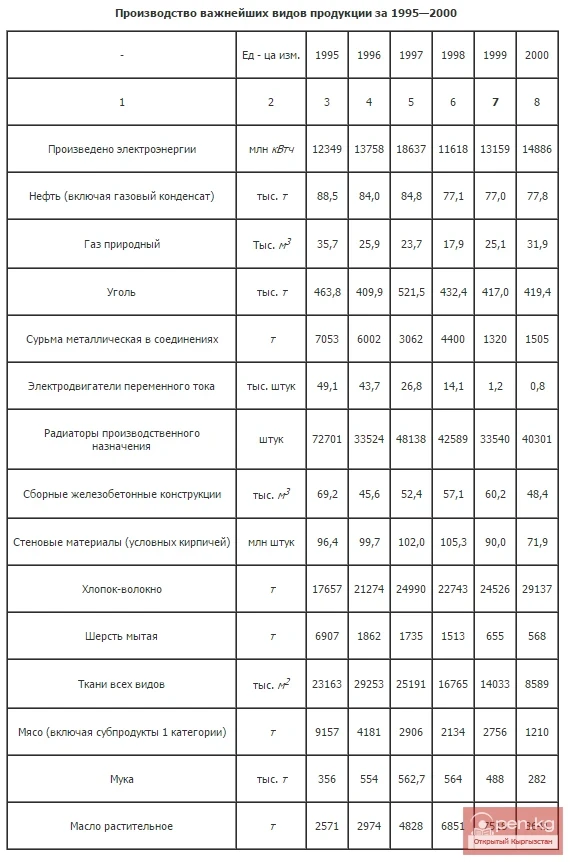

The main reasons for changes in the sectoral structure are the different levels of production decline and price growth of products. Raw material sectors occupy a leading position in the structure of the industries listed in Table 2 (57.4%), while processing and manufacturing sectors account for 25.4%, i.e., their share is more than 2 times lower. Such a sectoral structure in industry cannot ensure employment for the population; consequently, the unemployment rate remains at a medium-term perspective. The production of specific types of goods by industrial sectors is presented in Table 3.

In 2000, the growth rates of production compared to 1999 were as follows: electric power — 122.0, non-ferrous metallurgy — 108.6, construction materials industry — 104.7, light industry — 114.1, and food industry — 107.2%. Despite this, in 2000, a total of 53 enterprises in the industry were not operational. Of the 267 most important types of industrial products, in December 2000, the output of 114 items (42.7%) increased, 103 items (38.6%) decreased, and 50 items (18.7%) were not produced.