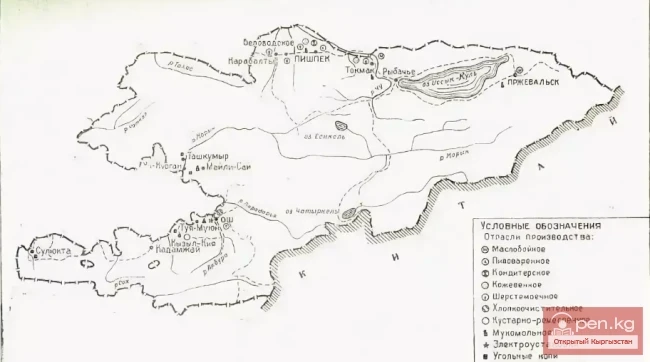

The food industry of pre-revolutionary Kyrgyzstan was represented by several small artisanal enterprises: mills, oil presses, and breweries, as well as salt mines. By the time the Kara-Kyrgyz Autonomous Region was established, there were only 28 enterprises here. Before the war, the food industry of the republic grew significantly. New sectors emerged: meat, dairy (14 butter and cheese factories), sugar, winemaking, baking, and others.

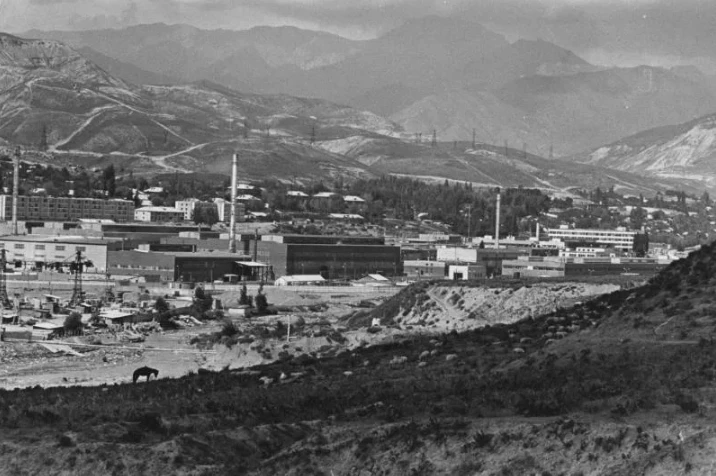

In the 1930s, large enterprises were built: the Osh meat processing plant (1930), the Bishkek (Frunze) meat processing plant (1931), the Bishkek tobacco factory (1935), the Bishkek bread factory (1940), and others. During the Great Patriotic War, sugar factories began operating based on evacuated enterprises: Novotroitsky, Tokmok, Belyovodsky; the Tokmok fruit and vegetable canning factory and the Jalal-Abad vitamin and canning factory. In the post-war years, many enterprises were fundamentally re-equipped, fitted with new technology, high-performance machines, and units.

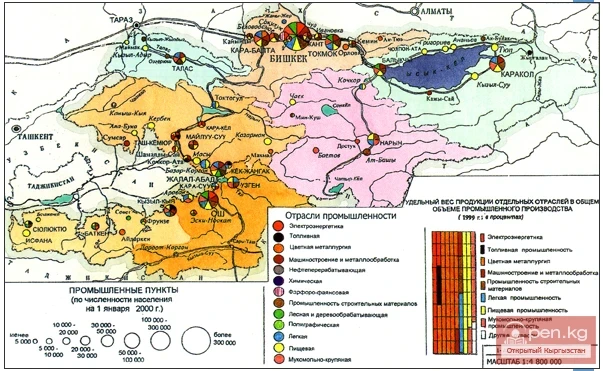

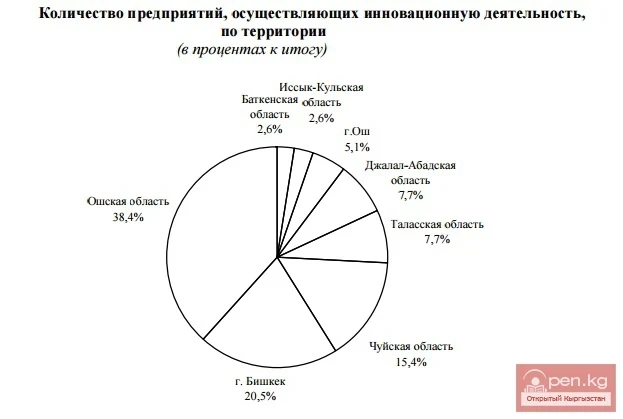

The food industry is one of the priority sectors of the republic's industry. The food industry sectors are mainly based on the processing of local raw materials for domestic consumption. In the structure of the gross industrial output, the food industry accounts for about 20% and over 10% of the export volume (sugar, fermented tobacco, food alcohol).

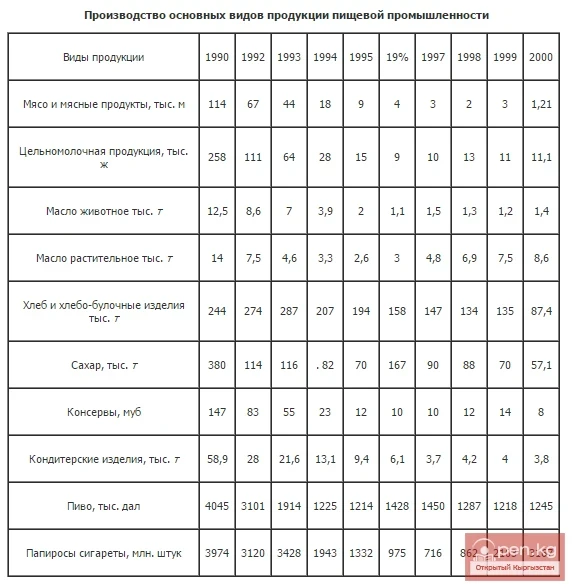

During the transition to market relations, the food industry of the republic found itself in a deep crisis. From 1991 to 2000, the production of food industry products as a whole decreased. In 2000, production reached about 15% of the 1991 level. The volumes of industrial output of the main nomenclature of food products were significantly reduced: flour, bread, bakery products, vegetable oil, dairy products, meat products, sugar, and others. In 1995, there was the largest decline in food industry production in sectors completely dependent on the development of agriculture in the republic (sugar, tobacco, meat, etc.). The decline in production was accompanied by structural changes in the industrial production of food products, related not to the growth of production in individual sectors, but to different rates of their decline. The overall production volume decreased by 42.6% from 1994 to 1999, but despite this, in 1997-1998, a certain trend of stabilization in food and flour-grain industries began to emerge. The physical volume index in the food industry in 1997, compared to 1996, was 103%, and in the flour-grain and feed industries, it was 118%. In 1999, agricultural product processing enterprises produced goods worth 8063.2 million soms, with a physical volume of 87.5% compared to 1998, including in the food industry, goods worth 4988.1 million soms, with a physical volume of 88%, and in the flour-grain and feed industries, 3075.1 million soms and 86%. Production growth in 1999 was achieved in the meat (13%), tobacco (9.7%), oil and fat (9.5%), and baking (1.1%) industries. The share of food industry exports in the total export volume in 1999 was 4.2% (25.1% in 1996). The decline was due to the uncompetitiveness of sugar production and the loss of major consumers—Uzbekistan and Kazakhstan. Since 1996, export supplies of flour have increased, which grew sixfold from 1995 to 1999, i.e., 116.9 thousand tons of flour were sold. In 1999, flour was sold to Tajikistan at 36.1% and to Uzbekistan at 51.4%.

For five years, the rates of decline in the production of meat, sausage products, canned goods, cereals, bread, and bakery products were maintained. This is explained by the reduction in livestock, the increase in the share of flour and bakery product consumption, and the sharp decrease in the supply of local raw materials for industrial processing. Agricultural products are mainly sold on the market, exchanged for barter, or exported outside the republic. The republic has specialized enterprises for the production of a wide range of food products, tobacco, liquor, and other goods. The privatization of food industry enterprises has almost been completed. In 2000, there were about 600 food and processing industrial enterprises, including 22 food enterprises (for vegetables, fruits, grapes, etc.), 26 dairy, 18 flour-grain and feed enterprises, 15 meat processing plants, 5 sugar factories, 6 tobacco factories, 10 confectioneries, 5 liquor factories, 7 breweries, 15 enterprises for winemaking and non-alcoholic beverages, as well as a number of mini-workshops and mills. The number of people employed in the industry is 21,000, or about 16% of all employed in industry. In 2000, the main sectors of the food industry were: meat, dairy, tobacco, sugar, liquor, winemaking, confectionery, fruit and vegetable, and others.

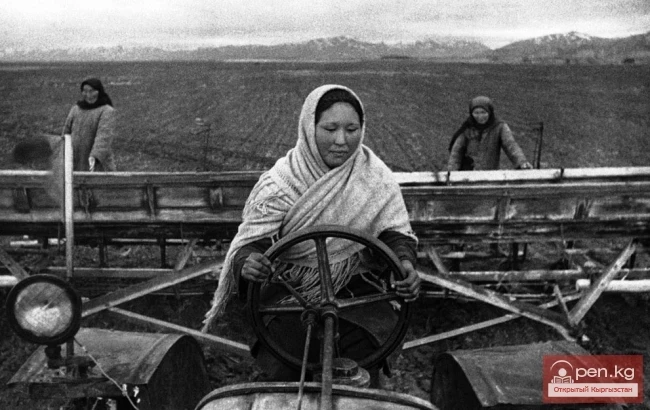

Meat Industry. The natural and climatic conditions of the republic and the historically established skills of the population predetermined the wide development of livestock sectors. From 1925 to 1984, the number of cows increased by 3.2 times, and sheep and goats by 4.3 times. Poultry farming also saw significant growth during these years. The steady growth of agriculture and the development of the livestock sector provided the creation of a raw material base for the meat industry. The processing of livestock and poultry by meat processing plants and poultry farms increased by 1.3 times from 1965 to 1983.

The crisis in agriculture, the decline in livestock and poultry numbers led to a decrease in meat production: from 1991 to 1996 by 23.3%, with a decline in industrial meat processing of 95.7%. In Kyrgyzstan, meat and meat products were produced: (in 1990—113.8 thousand tons) in 1996—4.1 thousand tons, in 1999—3 thousand tons, in 2000—1.21 thousand tons. In 1996, the production value was 97.1 million soms, in 1999—88.0 million soms, in 2000—45.4 million soms. The sector has a total of 81 enterprises (including 15 meat processing plants) and mini-productions. The largest are: the joint-stock company "Bishkek Meat Canning Plant," the joint-stock company "Töshtyk" (Karakol Meat Processing Plant), the joint-stock company "Kelechek" (Osh Meat Processing Plant), the joint-stock company "Kainy" (Kainy Meat Processing Plant), and others. The meat processing plants in the republic are equipped with equipment for the production of dry animal feed, food fats and oils, as well as medical preparations. In the republic, 1262 people work in the meat industry (1999).

Dairy Industry. In pre-revolutionary times, dairy products and butter were made only in individual private households using primitive methods. There was not a single industrial-type milk processing enterprise in the republic. After 1917, milk processing enterprises emerged in cities and large rural settlements of the republic. The growth of milk production among agricultural producers led to an increase in processing production in industrial enterprises. From 1965 to 1983, the production of whole milk products (in terms of milk) increased by 2.5 times, animal butter by 1.4 times, fatty cheese and bryndza by 2.3 times, and ice cream by 2.5 times. In 1999, the republic produced 11 thousand tons, and in 2000—11.1 thousand tons of whole milk products. In Kyrgyzstan, there are 63 enterprises in the dairy industry (1999). The largest enterprises include: the joint-stock company "BishkekSüt," the joint-stock company "Ak-Süt" (Belyovodsky Dairy Plant), the Tokmok Dairy Plant for cheese production—Kyrgyz-Swiss joint-stock company "Süt-Bulak," the joint-stock company "Ak-Jalga" (Kyzyl-Suu Cheese Plant), the joint-stock company "Elvest" (Bishkek), "Eridan-Süt" (Kara-Balta). There are also mini-productions in farms and peasant households. In the dairy industry, 2047 people work (1999).

The enterprises of the fruit and vegetable industry in Kyrgyzstan are small in scale (except for a few). In the early 1990s, over 120 types of fruit and vegetable preserves were processed in the republic, including more than 14 types from non-traditional and wild raw materials. The largest enterprises are: the joint-stock company "Tokmok Canning Factory," the limited liability company "TokmokFruitVegetable," the joint-stock company "Gyulazik" (Bishkek Canning Plant), and the open joint-stock company "Zhemish" (Issyk-Kul Fruit and Vegetable Soviet Farm Combine).

Fruit and vegetable processing enterprises can annually process up to 10 thousand tons of vegetables, 60 thousand tons of tomatoes, about 40 thousand tons of fruits and berries, and have equipment for processing apples into concentrated juice with a capacity of up to 10 thousand tons of apples per year. The enterprises are equipped with automated lines for processing tomatoes into paste and juice, cucumbers, patissons, and for producing compotes, jams, and jellies.

Industrial enterprises for alcoholic and non-alcoholic beverages are represented by such large enterprises as: the joint-stock company "Bishkek Liquor and Vodka Plant," the joint venture "Bakay" (Kara-Balta), the joint-stock company "KyrgyzChampagne," the joint-stock company "Salkyn" (Jalal-Abad Brewery), "Bishkek Brewery," the joint-stock company "Adis" (Belyovodsky), the joint-stock company "Ala-Too" (Alamudun District), and other mini-productions. In 1999, 994.1 thousand dal of liquor and vodka products, 1217.5 thousand dal of beer, and 390.9 thousand dal of alcohol were produced. In 2000, liquor and vodka products—1370.8 thousand dal, beer—1244.6 thousand dal, alcohol—638.5 thousand dal.

The beginning of the development of viticulture and winemaking in the republic dates back to 1944 when the Lenin name vineyard was organized in the Chui Valley. In the following years, vineyard farms were created: "Ala-Too," "Chui," "October," and named after Krupskaya. In 1980, the total area of vineyards in the republic occupied 8 thousand hectares, with a gross grape harvest of 70.3 thousand tons. The production of grape wine in 1995 decreased by 10%, champagne by 30%, and cognac by 48%. Wines produced by the joint-stock company "KyrgyzChampagne" (1957) from local raw materials have always been distinguished by high quality. In 1966, this joint-stock company produced 2 million bottles of cognac and 2 million bottles of champagne. At the first international competition for cognac producers in the city of Tiraspol, Republic of Moldova, in 1966, they were awarded a gold medal: Kyrgyz cognac "1000th Anniversary of the Epic of Manas," brand "KS"; a silver medal: "Manas," brand "KVVK"; "Jubilee," brand "KB"; a bronze medal—brand "KB"—five-star and three-star. In 1999, 30.4 thousand dal of cognac and 67.7 thousand dal of champagne were produced in the republic, and in 2000, cognac—27.5 thousand dal, champagne—43.2 thousand dal.

Sugar Industry. It saw significant development in the early 1940s. In the 1940s and 1950s, the Novotroitsky, Kant, Tokmok, Belyovodsky, and other factories were built. The sown areas for sugar beets exceeded 50 thousand hectares, with a gross harvest of 1 million 900 thousand tons. Due to the decrease in the sugar content of beets and the decline in their yield since the mid-1980s, the production of sugar beets (factory) was halted (resumed in 1990). The sugar industry of the republic is represented by 3 enterprises. The largest are: the joint-stock company "Koshoy" (Ak-Suu Sugar Plant), the joint-stock company "Kainy-Kant" (Kainy Sugar Plant), and the joint-stock company "Bakay." In 1999, 70,324.4 tons of sugar were produced worth 1,176.7 million soms, and in 2000—57,137.3 tons worth 1,028.1 million soms.

In the republic, the Ak-Suu Corn Processing Plant has been built, with a factory for the production of glucose-fructose juice (projected capacity of 213 thousand tons of corn processing). It produces the following types of finished products: glucose-fructose syrup, dry starch, modified dry starch for baking, modified dry starch for the textile industry, dry granulated feed, raw corn oil—evaporated extract, protein-phosphatidic concentrate.

Confectionery industrial production in Kyrgyzstan has only developed in recent years after a decline. The first mechanized confectionery production was established in 1956 at the bread factory. In the following years, the confectionery production at this factory was reconstructed, and specialized sections for the production of caramel, soft candies, etc., were created. In 1974, the Bishkek Confectionery Industrial Production Association was organized (with an annual output of 26 thousand tons of confectionery products). In 1999, 4,017.4 tons of confectionery products were produced, and in 2000—3,765.4 tons. The confectionery industry is represented by 6 large joint-stock enterprises, including the joint-stock company "Tatty," Bishkek Confectionery Plant, joint-stock company "Tunguch-Kant," joint-stock company "Eastern Sweets," Jalal-Abad Confectionery Factory, and the joint venture "Iris." In addition, many joint-stock companies in the dairy industry, sugar factories, and enterprises of the Consumer Societies Union have confectionery workshops.

The baking industry in Kyrgyzstan began to develop only after the revolution. Before 1917, bread baking was at the level of home and small-scale production. In 1973, the baking enterprises of the republic produced 248 thousand tons (in 1940—113.6 thousand tons), in 1996—70.2 thousand tons (in 1990—244.1 thousand tons), in 1999—135,131.3 tons, and in 2000—87,443.3 tons of bread and bakery products. There are bread factories in almost all cities and large settlements in the republic. The largest enterprises in the sector include the joint-stock company "Bishkek-Nan," the joint-stock company "Osh-Nan," the Tokmok Bread Factory, the Jalal-Abad Bread Factory, the joint-stock company "Kara-Balta Bread Factory," and the joint-stock company "Gyulazik" (Osh Bread Factory). Mini-bakeries have also developed widely (in the republic, they account for almost 50% of the produced bakery products).

Tobacco Industry. Tobacco was first cultivated in the republic in 1890 on an area of 70 hectares. Tobacco production saw significant development from 1929 (initially in the Chui Valley, then in the Talas Valley and southern regions of the republic). In 1932, the Bishkek Fermentation Plant was built, and in 1933—a tobacco factory. From 1940 to 1983, tobacco areas expanded by 5.3 times (with yield increasing by 3.6 times). In 1991, the sown areas in the republic were 20.7 thousand hectares, with raw tobacco production of 50 thousand tons. In subsequent years, with the transition to market relations, the number of tobacco-growing farms decreased or ceased to exist, leading to a sharp decline in tobacco production. In 1995, 17.6 thousand tons of raw tobacco were harvested, and 13.8 thousand tons were fermented. The production capacity was utilized at 33%. In 1996, 10,735.5 tons of fermented tobacco, 975.0 million pieces of cigarettes and cigars, and 640.6 tons of smoking tobacco worth 146.4 million soms were produced; in 1999—37,798.2 tons of fermented tobacco, 2,102.5 million pieces of cigarettes and cigars, and 573.9 tons of smoking tobacco worth 919.4 million soms; in 2000—31,167.8 tons of fermented tobacco, 3,168.6 million pieces of cigarettes and cigars, and 601.3 tons of smoking tobacco worth 1,340.1 million soms.

Tobacco product manufacturing is concentrated in 11 enterprises. The largest include: the joint-stock company "REEMSTMA—Kyrgyzstan" (with a capacity of 7 billion cigarettes per year), the joint-stock company "Sary-Altyn," the Kyzyl-Kyisky Tobacco Fermentation Plant, the Jalal-Abad Tobacco Fermentation Plant, the joint-stock company "Ayup-Bulak," the Osh Tobacco Fermentation Plant, and the joint-stock company "Osh Dyubek."

Industrial enterprises for oil and fat production include: the state joint-stock company "Ak-May" in Kara-Suu, Osh Region (with a capacity of 120 tons of margarine, 3 thousand tons of mayonnaise per year), the state joint-stock company "May" (Tokmok Oil and Fat Plant), with a capacity utilized at only 10-11%, and the Kyrgyz Starch and Syrup Plant. In 1996, 1,065.4 tons of animal fat and 2,973.9 tons of vegetable oil were produced; in 1999—1,235.7 tons of animal fat and 7,518.2 tons of vegetable oil; in 2000—1,383.6 tons of animal fat and 8,640.6 tons of vegetable oil. There are mini-productions of vegetable oil in the republic.

Alongside large specialized enterprises in the food industry of the republic, mini-workshops and small enterprises actively function, producing a significant portion of the products consumed by the population. In 2000, 2028 mini-mills, 1341 mini-bakeries, 319 workshops for the production of vegetable oil and mayonnaise, 309 mini-dairy workshops, 14 mini-fruit and vegetable workshops, 113 workshops for pasta production, 67 mini-workshops for beverage production, 230 confectionery workshops, 21 mini-workshops for ice cream production, 164 rice processing workshops, and 3 tobacco fermentation workshops were created. Most of them are located in the Chui region, employing 15,000 people. These mini-productions account for 60% of flour output, 30% of vegetable oil, and 70% of bread.

The flour-grain and feed industry of the republic grew particularly rapidly in the 1930s when there was an acute need for grain processing. In Kyrgyzstan, before the revolution, there were only 8 small mills, where 72 people worked in 1925. In the post-war period, large milling combines were built in Bishkek, Kara-Suu, Osh, Jalal-Abad, Karakol, Balykchy, Suluktu, and others. Alongside them, large new collective farm and state farm inter-farm mills developed. Now, in a market economy, many private mini-mills have emerged. Until 1991, the development of the milling sector and the production of bread products in the republic was consolidated into a single monopolistic conglomerate, which controlled all major milling production capacities, as well as feed production plants, bakery combines, and about 100 bakeries. This monopoly owned 80-90% of the republican stock, 100% of flour production, and 60% of bread products. Raw materials were supplied through the state order system.

Currently, most large milling combines operate at maximum capacity of 30-50% due to the significant growth of private mills of simple designs, which fully meet the needs of the local population. More than 343 enterprises operate in the republic. The largest include: the state joint-stock company "Issyk-Kuldan-Azyk," the limited liability company "BishkekMolkombinat," the "Jalal-Abad Bread Product Combine," the state joint-stock company "Kara-Suu-dan-Azyk," KAS "Kara-Balta" ("Kyrgyz Agribusiness Company"), and the state enterprise "BuuDay." In 2000, 281 million tons of flour were produced, of which 5-6% came from mini-enterprises.

Cereals are mainly produced by: the limited liability company "Bishkek Milling Combine," "Kara-Balta KAS."

The feed production began to develop in the 1970s and 1980s. Currently, the decrease in the number of livestock and poultry is related to feed. Since 1990, the production of feed has decreased. More than 10 large industrial enterprises for feed production operate in the republic. In 1996, 36,512.0 tons of feed were produced, in 1999—13,982.8 tons, and in 2000—9,008.4 tons; in 1996, products worth 946.7 million soms were produced, in 1999—3,075.1 million soms, and in 2000—2,171.0 million soms. The number of people employed in this sector is 5,564.