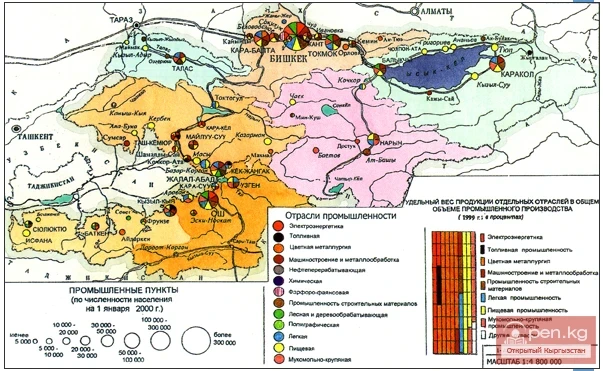

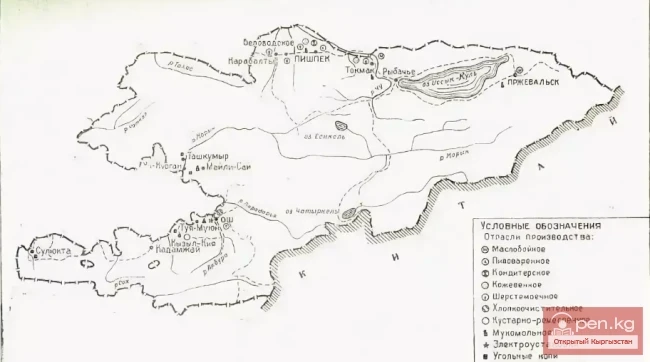

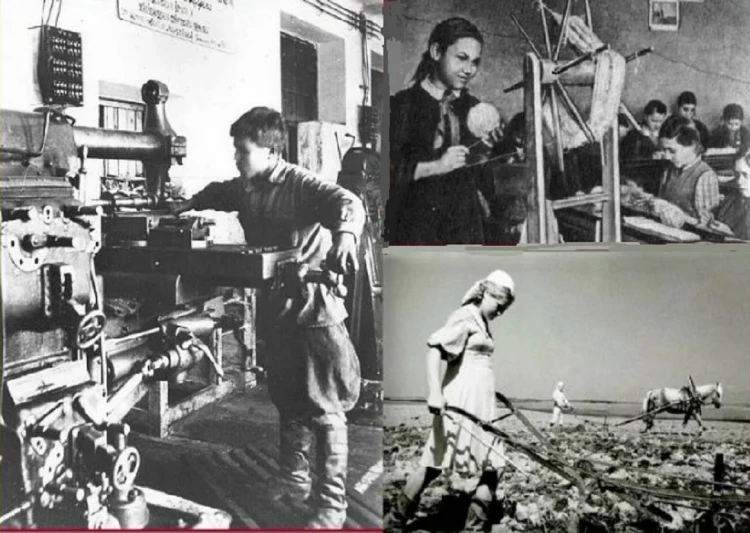

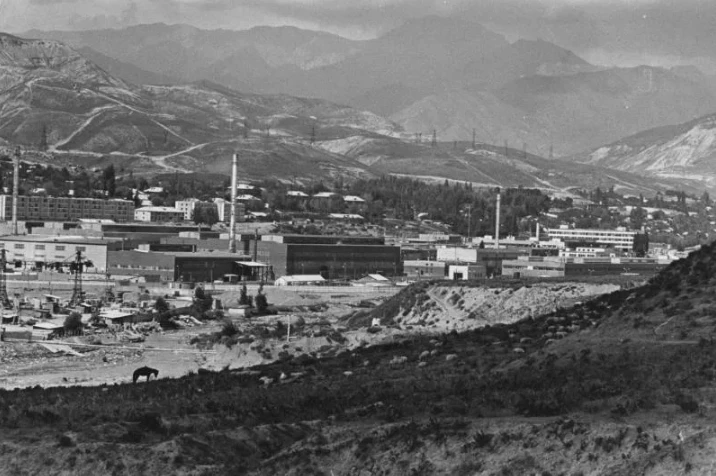

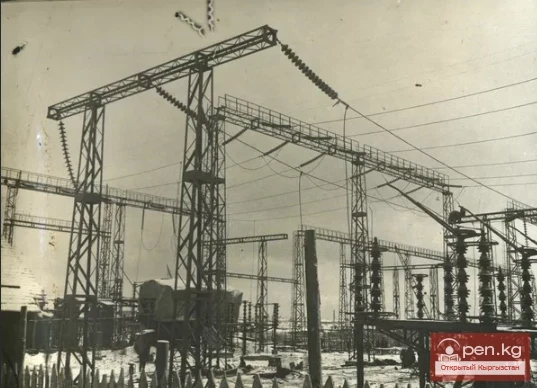

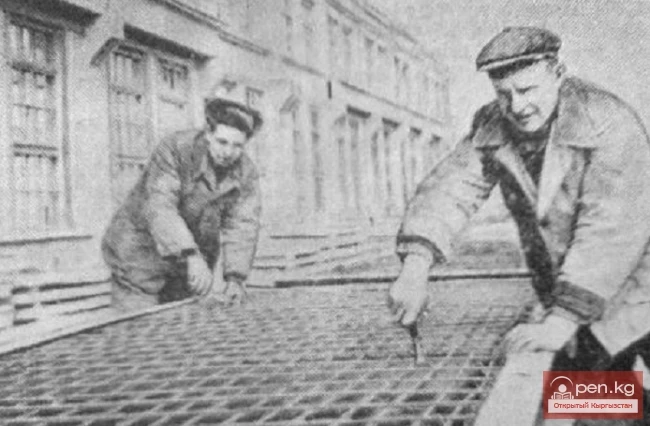

The light industry of Kyrgyzstan encompasses its three sectors: textile, garment, and leather-footwear. It accounts for 24% of the industrial workforce and 30% of the gross output of all industries, which ensures its priority in the economic potential of the republic. Before the October Revolution, there were only a few private semi-handicraft enterprises in Kyrgyzstan for the primary processing of agricultural raw materials—wool washing and cotton cleaning points. During the pre-war five-year plans, industries of light industry were created and developed intensively based on local agricultural raw materials. From 1928 to 1940, 15 large enterprises were built and put into operation, including 3 cotton cleaning plants, 6 factories for the primary processing of bast crops, a silk-reeling plant, spinning-weaving, garment, footwear factories, and 2 leather factories. During the Great Patriotic War, the light industry of the republic expanded due to evacuated enterprises, which led to the establishment of the Frunze Knitting Factory, garment and footwear factories in the cities of Karakol, Naryn, Talas, Osh, and Jalal-Abad. During the war years, the number of enterprises increased from 16 to 29, and their production capacities grew. In the post-war years, enterprises were reconstructed, more advanced technological processes were introduced, and new automatic equipment was installed. Significant growth in light industry occurred in the 1960s. In 1963, the woolen and cloth combine (Bishkek) was commissioned. Footwear and 2 garment factories were put into operation, leather factories and knitting factories were reconstructed and expanded. Following them, in the 1970s, the first stage of the Osh cotton production association, the Tokmok wool primary processing factory, the "Cholpon" footwear firm, the footwear factory in Kyzyl-Kiya, the Vasiliev knitting factory, and others were launched.

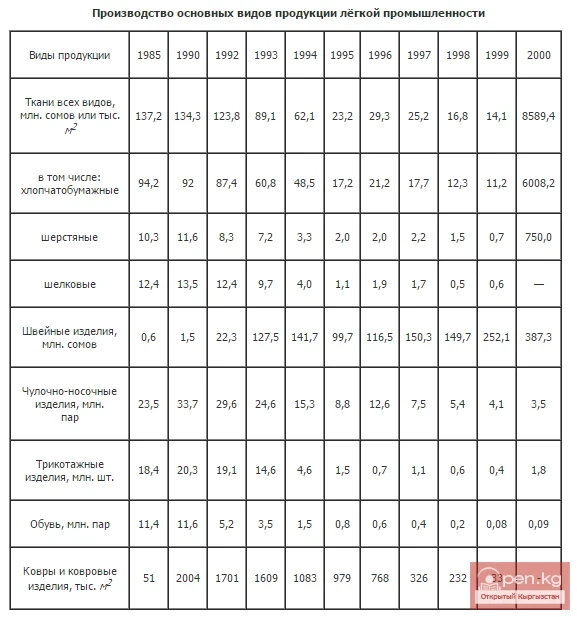

Currently, light industry still holds a leading position in the economy of the republic, providing high employment for the population. Alongside other goods, it produces mass-demand products for the local market. There are broad opportunities for export to near and far abroad. It is significant that light industry is a highly efficient, quickly recouped sector that provides itself with raw materials produced in the republic. Overall, the growth rate in the sector for the year 2000 was 105.4%; textile and garment enterprises produced goods worth 2,346.6 million soms, while leather enterprises and those producing footwear and other leather goods produced goods worth 81.2 million soms. The light industry includes more than 200 industrial enterprises forming textile-knitting, garment, and leather-footwear complexes that produce a wide range of goods. If in the early 1990s light industry produced 30% of the total industrial output, by 1999 its output had dropped to only 5.7%. In 1994, 99.7% of the capacities of the leather and haberdashery industry were utilized, while in 1999, only 7% and up to 3% of the capacities in the sectors producing and releasing silk fabrics, knitted products, furs, and products made from natural fur were utilized. The production of fabrics, knitwear, and footwear significantly decreased. In 1999, the export of cotton fabrics to Russia, compared to 1994, decreased by 38%, to Uzbekistan by 8.7 times, and the export of wool products to these countries completely ceased. The decline in production volumes in light industry enterprises is mainly due to a lack of raw materials. The industry operates based on natural raw materials and products made from them. The weakening of production dynamics in the textile industry was linked to changes in the state of agriculture (decreased areas of cotton plantations and reduced yields). Enterprises in the processing industry face serious difficulties in ensuring leather raw materials. If in the early 1990s, 4.2 million pieces of small livestock skins were harvested, by 1998 the volume of skin harvesting had decreased to 0.5 and 0.2 million pieces.

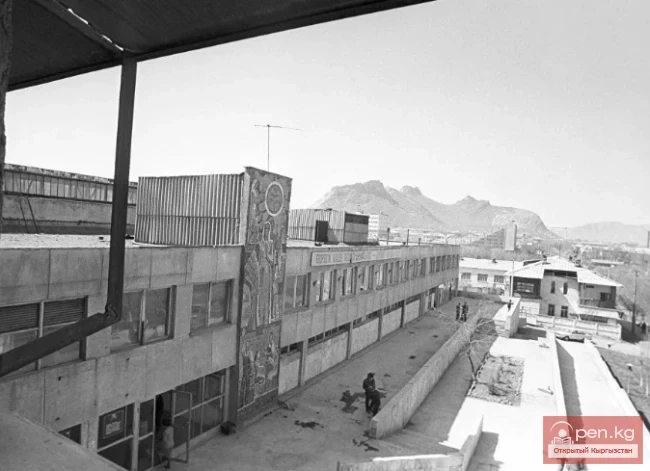

The textile industry of the republic is predominant over others; it is represented by enterprises in six sub-sectors, including: cotton—AO "Textilshchik" (Osh cotton production association)—the share of this enterprise's output is one-fifth of the total volume of the sector. The potential capacity of AO "Textilshchik" under stable operation reaches 1 billion soms per year. Wool—AO "KKSK" (Kyrgyz Woolen and Cloth Combine), AO "Kasiiet" (Tokmok Woolen-Spinning Factory), AO "Azem Kilem" (Kara-Balta Carpet Combine). Silk—AO "Osh-Jibek" (Osh Silk Combine) produces primary processing of cocoons and sells them as semi-finished products to India, Pakistan, and China. Currently, silk fabric is not produced due to its uncompetitiveness in the external market and high cost in the domestic market. Hemp-jute—Bishkek Kenaf Factory. Primary wool processing—AO "Ak-Bula" (Tokmok POSh Factory) produces the cleaning of raw wool. Knitting—AO "Ilbirs", AO "Edelweiss", AO "Baipak", AO "Zhyldyz", OsOO "Zaman", firm "Vesta", and others produce knitted products, hosiery, outer knitwear, underwear knitwear, and terry products.

The garment industry is represented by factories located in the cities of Bishkek, Osh, Karakol, Talas, Jalal-Abad, and others, with a total workforce of over 6,100 people. The share of the garment industry in the total output of light industry products is 16.7%. The range of products produced is diverse: AO "Aigul" specializes in the production of coats and jackets; AO "Teskim" produces women's dresses and men's shirts; AO "Bishkek Garment Factory of VLKSM" produces suits and trousers.

In 2000, the index of the physical volume of output in the textile and garment industry compared to 1999 was 103.3%. The production of canvas fabric increased by 7.1%. During the same period, the output of silk fabrics decreased by 72%, knitted products (hand and machine knitting) by 51.9%, carpets and carpet products by 34.8%, and knitted socks (hand and machine knitting) by 13.1%.

The leather-footwear and fur industry is represented by enterprises such as: SP "Bulgaary", AO "Ak-Maaral", AOOOT "Bistail", the Zhanı-Zher Children's Footwear Factory "Byobek", the Kyzyl-Kiya Footwear Factory, and others. The range of products produced by these enterprises is diverse in composition. In 2000, the production of leather, leather goods, and footwear overall increased by 28.8%. The growth in production rates was influenced by the increase in the output of suitcases, bags, and other leather goods (by 32.3%), footwear (by 9.7%), and natural leather (by 9.2%).

In 1999, the share of light industry products in the total volume of industrial production was 5.7%, while the number of employed was 16.5%.

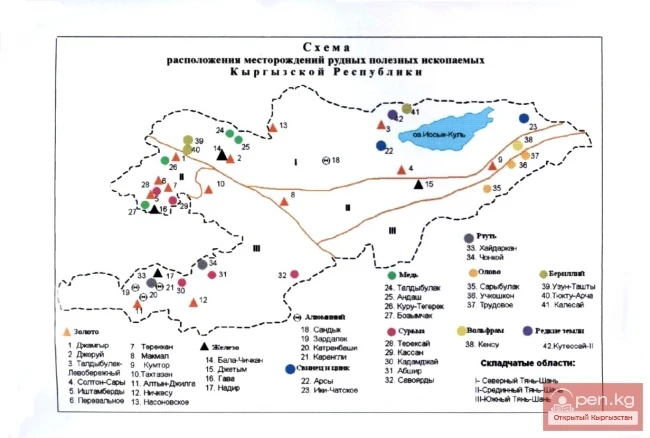

The orientation of light industry towards the production of finished products allows for a reduction in the export of cheap raw materials and semi-finished products (cotton, wool, leather), ensuring more complete processing of these materials locally using available capacities. The development of the industry is largely determined by the capabilities of the raw material base. The republic produces raw cotton, mulberry silkworm cocoons, and ensures the preparation of leather raw materials.

In light industry, small and medium-sized enterprises are successfully developing. Working in conjunction with large enterprises, this sector of the industry ensures deeper processing of local raw materials and production waste, producing consumer goods—garment and knitted products, yarn, footwear, and engaging in the processing of leather-fur raw materials, the production of textile and leather fittings, and various haberdashery goods. Small enterprises producing folk art and handicraft products manufacture, for example, shyrdaks, tush-kiyizs, clothing, footwear, and products made from leather raw materials with national ornamentation.