On the Consistent Work on the Modernization of Production Complexes and Repair Base of the Structural Units of the State Enterprise "National Company 'Kyrgyz Temir Zholu'"

To achieve its goals, the enterprise is systematically updating its material and technical base by implementing the latest technologies for diagnosing and repairing rolling stock. In particular, modern equipment and specialized systems are being procured, which allows for increased accuracy in identifying faults, expedited repair processes, and compliance with established safety standards.

These changes in the repair infrastructure not only boost productivity but also improve working conditions for specialists and reduce risks associated with the operation of rolling stock.

Priority in Locomotive Management

The branch of the state enterprise "National Company 'Kyrgyz Temir Zholu'" responsible for locomotive management plays a key role in ensuring the stable and safe operation of diesel locomotives. This directly affects the fulfillment of plans for freight and passenger transportation, as well as the safety of train movements. The main task of the branch is to maintain the operability of the locomotive fleet and ensure its efficient operation.

In this context, the branch is actively working on the maintenance and monitoring of the operational characteristics of locomotives. Special attention is given to safety issues, with measures being developed to prevent emergency situations and violations.

Modern Technologies in Diesel Locomotive Repair

Over the past five years, as part of the branch's modernization, new test benches with software have been acquired, which eliminate the human factor in the process of repairing locomotive equipment. This has significantly improved the quality of repairs and diagnostics of diesel locomotive spare parts, which, in turn, has reduced the number of unscheduled repairs.

In 2025, there are also plans to retrofit the TE33A and TE10M locomotives with new train control safety systems, BORT. This system is more economical and functional compared to the outdated KLUB system, providing control over diesel fuel consumption and the presence of video surveillance.

Updating Laboratory Equipment

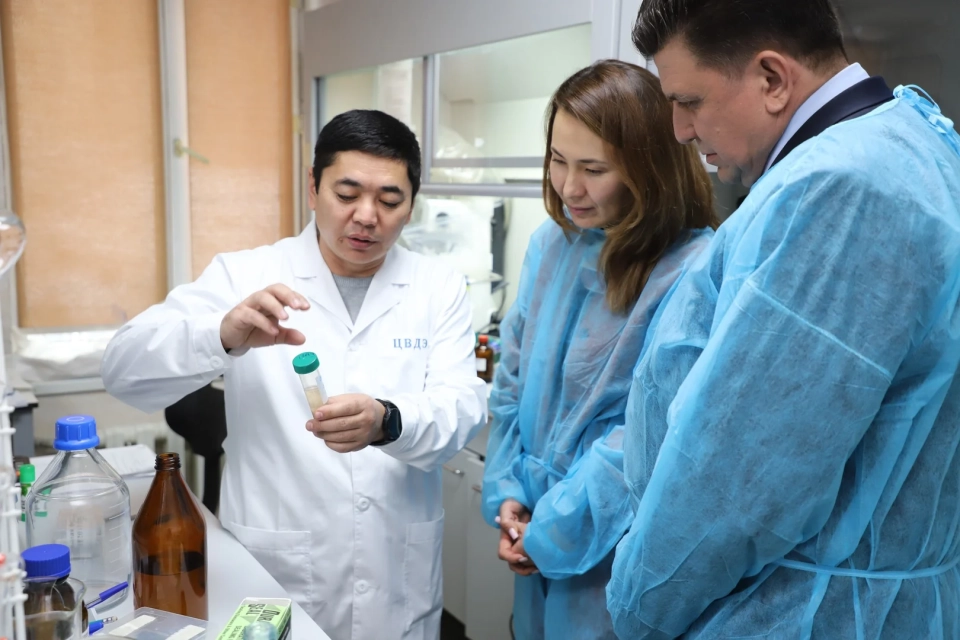

Additionally, the chemical laboratory of the branch has updated its equipment, including photoelectric photometers and analyzers, which has increased the reliability of determining the quality of fuel and lubricants.

As part of the modernization project, new types of locomotive repairs that were previously carried out abroad are being mastered in collaboration with LLC "NPC Promtech," thanks to the acquisition of new equipment.

Creation of a Modern Repair Complex

The modernization project aims to create an efficient repair base, which will allow for comprehensive repairs of locomotives on-site, minimizing the need to engage external contractors.

The main goals of the project are:

- Ensuring the comprehensive repair of locomotives at the branch's base.

- Reducing operational costs through increased efficiency.

- Improving the reliability and safety of the transportation process.

- Creating new jobs and developing a skilled workforce.

- Implementing modern service standards and automating processes.

This will attract orders from other countries for the repair and maintenance of locomotives, expanding the production capabilities of the branch.

Modernization in the Non-Destructive Testing Laboratory

The non-destructive testing laboratory acquired modern ultrasonic flaw detection trolleys in 2022, which improved the accuracy and timeliness of defect detection in rails. In 2025, plans are in place to update old equipment with more modern devices, which will also impact work efficiency.

Ensuring Reliable Power Supply and Signaling

The branch responsible for power supply and signaling is modernizing its equipment to ensure the reliable operation of safety and communication systems on the railway. The implementation of new technologies, such as LEDs, also contributes to energy savings.

Wagon Management Branch

The branch carries out the maintenance and repair of wagons, implementing modern working methods and equipment to enhance the quality and efficiency of repair processes.

Plans include the installation of new systems for dismantling and assembling wagon parts, which will significantly reduce repair time and increase throughput.

Updating Equipment in the Track Management Sector

The modernization of the production base of the branch in track management continues, focusing on updating the fleet of machinery and equipment. The introduction of new mechanisms and vehicles allows for increased work volumes and improved logistics, leading to higher productivity.

Thus, the state enterprise "National Company 'Kyrgyz Temir Zholu'" continues to actively develop, implementing modern technologies and improving the quality of its services to ensure the reliability and safety of railway transport.

Read also:

Tokayev: Kazakhstan has entered a new stage of modernization

Curl error: Operation timed out after 120001 milliseconds with 0 bytes received...

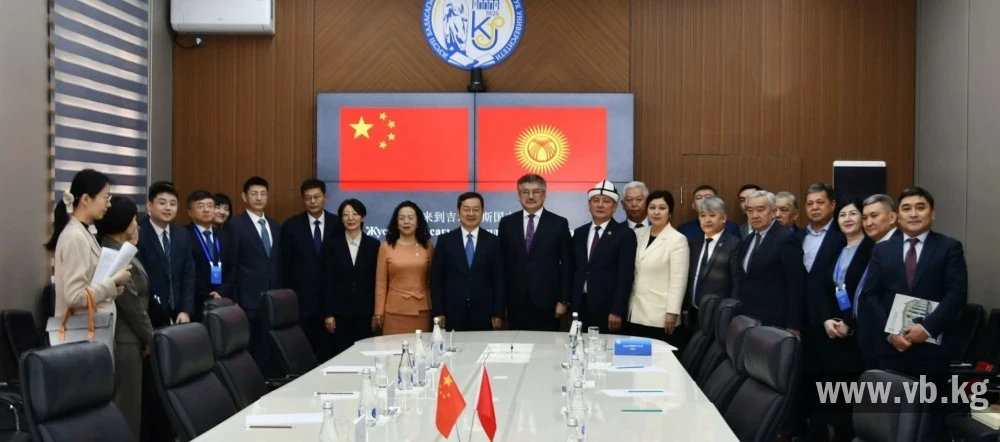

Bishkek and Beijing Collaborate in Practice, Not Just Words, in a New Era

A briefing was held at the Kyrgyz National University named after J. Balasagyn, dedicated to the...

The new law will ensure food safety "from farm to table" — text

On November 12, President Sadyr Japarov approved the law "On Ensuring Food Safety"...

OJSC "Dos-Credobank" announces the start of sales of subordinated bonds

alt="JSC 'Dos-Credobank' launches the sale of subordinated bonds" /> Invest...

How the Political Architecture of Kazakhstan Will Change

Last weekend, following the issuance of a decree, 130 participants gathered for the first meeting...

Kazakhstan Wants to Become the Transit Hub of Eurasia. What Obstacles Are in the Way?

The second line of the Dostyk — Moyinty railway has been opened in Kazakhstan. The country's...

"Adilet" analyzed the draft law on the confiscation of property before a court decision

On the Unified Public Discussion Portal, an analysis of the draft law "On Amendments to...

What the New Consumer Credit Law Is About — Text

- The President of Kyrgyzstan, Sadyr Japarov, has approved a law concerning amendments to certain...

President Sadyr Japarov delivered a speech at the IV People's Kurultai

Curl error: Operation timed out after 120001 milliseconds with 0 bytes received...

Bishkek-2050: An Ambitious Master Plan or Another Utopia? Opinions of Architects

The Research Institute of Prospective Urban Development from St. Petersburg presented a master plan...

"Sometimes Harsh, but Necessary". How Entrepreneurs Assess the Year 2025

According to the Central Bank, Kyrgyzstan is forecasting an economic growth of more than 10% by the...

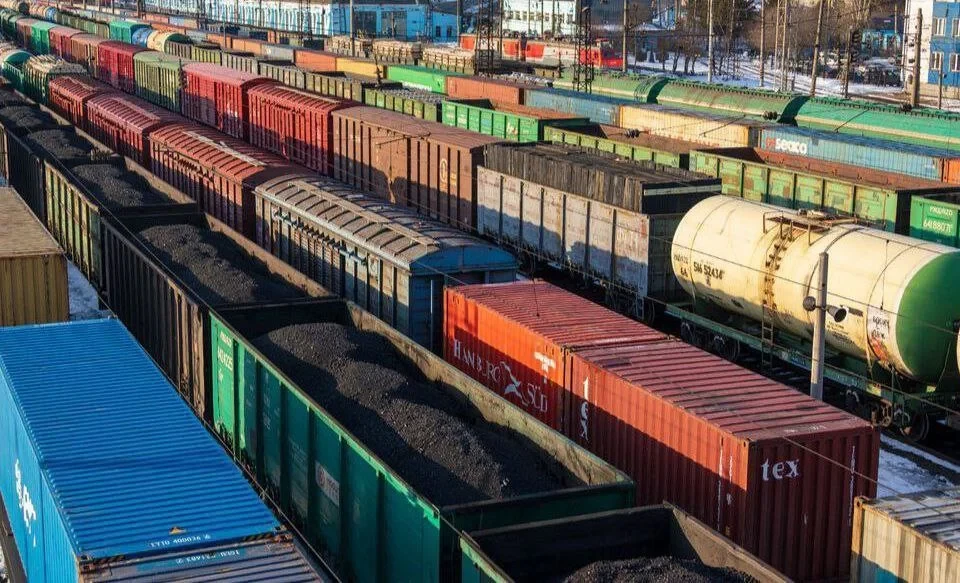

The Railways of Kyrgyzstan Achieve Record Transportation Volumes

The length of the Kyrgyz railway is 424.6 km, and it plays a crucial role in the country's...

UN: Modern Slavery is Gaining Momentum

According to the ILO, cases of forced labor and forced marriages have significantly increased over...

Europe is Closing Its Borders. The Fight Against Migrants Intensifies Ahead of the Crucial Year 2026

Important changes in migration policy have occurred after 27 EU countries agreed on the details of...

President Sadyr Japarov responded to Atambayev's accusations

- Hello, Sadyr Nurgoyevich. We would like to get your comment regarding the recent address by...

Russian and Ukrainian Drone Manufacturers Purchase Components from the Same Chinese Companies

This approach allows both sides to quickly obtain the necessary equipment; however, as Babенко...

Summit in Gabala. How is the CSTO transforming Central Asia into a competitive power center?

At the twelfth summit of the Organization of Turkic States, which took place in Gabala, the main...

Oil or Rare Earth Elements: What Will Determine the Future of the Global Economy?

The 20th century was the era of oil, but modern realities, such as rare earth elements,...

The Person Inside the Brain: Everyone Lives in Their Own Mental Umwelt

Curl error: Operation timed out after 120001 milliseconds with 0 bytes received...

In the city of Orlovka, nearly 60 million soms in investments were attracted over the year: What projects have been implemented

In 2025, the Orlovka city administration managed to attract funding amounting to 59.8 million soms...

Sadyr Japarov spoke at the IV People's Kurultai (text of the speech)

Today, December 25, the President of Kyrgyzstan, Sadyr Japarov, addressed the people, the deputies...

Sadyr Japarov signed the updated edition of the constitutional law "On the National Bank"

- President Sadyr Japarov approved a new edition of the constitutional law "On the National...

Stable, Pragmatic, and Gradually Developing Relations - Ambassador of Kazakhstan Rapil Zhoshybaev (Interview)

The Extraordinary and Plenipotentiary Ambassador of Kazakhstan to Kyrgyzstan, Ravil Zhoshbaev,...

Strengthening Cooperation Between the EU and Kazakhstan for a Sustainable Future

The parties strive for long-term and stable cooperation Kazakhstan and the European Union have a...

Taalatbek Masadikov became the Secretary General of the CSTO. Interview

The Secretary General of the CSTO, Taalatbek Masadykov, answered questions from the editorial...

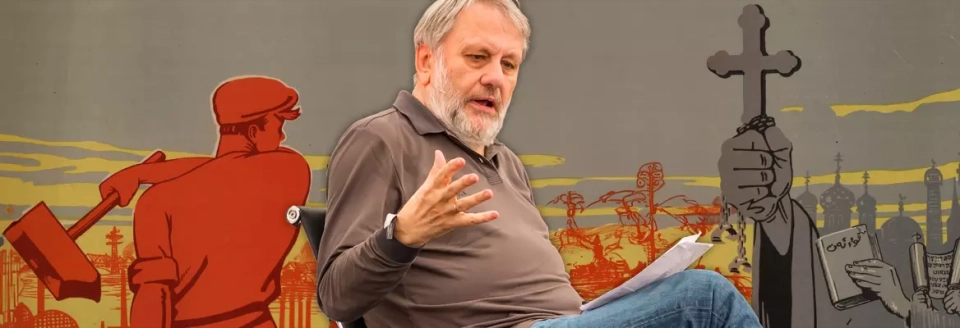

Slavoj Žižek: Why We Are Still Alive in the Dead Internet

Slavoj Žižek emphasizes that when we hear about the control that artificial intelligence begins to...

Amendments Made to the Action Plan for the Implementation of the State Program to Increase the Share of Cashless Payments

- Adjustments have been made to the Action Plan aimed at implementing the State Program for...

Mars Sariyev: State Visit to Pakistan Goes Beyond Traditional Diplomacy

The visit of the President of Kyrgyzstan, Sadyr Japarov, to Pakistan has become a landmark event...

Atom or Darkness. Nuclear Power Plants as the Last Chance for Kyrgyzstan?

Recently, the Prime Minister of Kyrgyzstan, Adylbek Kasymaliev, spoke about the prospects of...

The Mechanics of Betting Odds: From Mathematics to Reality

Modern betting is a complex process where mathematical methods, big data analysis, and psychology...

In Kyrgyzstan, it was proposed to raise the requirements for the charter capital of banks

The National Bank of Kyrgyzstan has presented a draft resolution for public discussion, proposing...

Delegate of the Kurultai: We were impressed by the new waste recycling plant

As part of the excursion program organized by the Bishkek city hall for the delegates of the IV...

Competition of Transport Corridors in the Middle East Enters a New Stage

According to information from various sources in the Middle East, a high-speed railway project is...

Recruitment of Volunteers for the Protection of Important Facilities Has Begun in the Regions of Russia

In Russia, an active program has begun to recruit volunteers into special units that will be...

The opening of Depot No. 1 after reconstruction took place in Bishkek.

The opening of the updated depot No. 1 took place in Bishkek as part of an excursion program...

Sadyr Japarov: "Kyrgyzstan today especially needs youth with deep knowledge"

Today, October 31, President Sadyr Japarov emphasized the importance of youth possessing...

Urmаt Akuluev: "The main thing is to create conditions for people"

As part of the reforms implemented by the Ministry of Justice of the Kyrgyz Republic, measures are...

How China and Russia are Joining Forces to Conquer the Arctic

According to information from the Telegraph, the Arctic has become a stage for strategic rivalry...

FAO has provided laboratories in Kyrgyzstan with equipment for detecting GMOs

On December 18, a transfer of modern laboratory equipment from the Food and Agriculture...

A Recreation Park Opened in Tyup

In the village of Issyk-Kul, located in the rural district of Issyk-Kul in the Tyup region, the...

Transport Workers' Day. The Work of Drivers is the Key to the Uninterrupted Operation of the Kumtor Mine

Every year on October 25, Kyrgyzstan celebrates the Day of Workers of Automobile Transport and...

The Accounts Chamber of Kyrgyzstan Revealed Ineffective and Misallocated Use of Funds in the "Education for the Future" and "Strengthening the Foundations of Learning" Projects

During the audit, it was established that the project directions generally align with the stated...

Why Does the Republic Need Tourism?

It is profitable, of course, profitable. But why does such a lucrative sector not yield the...